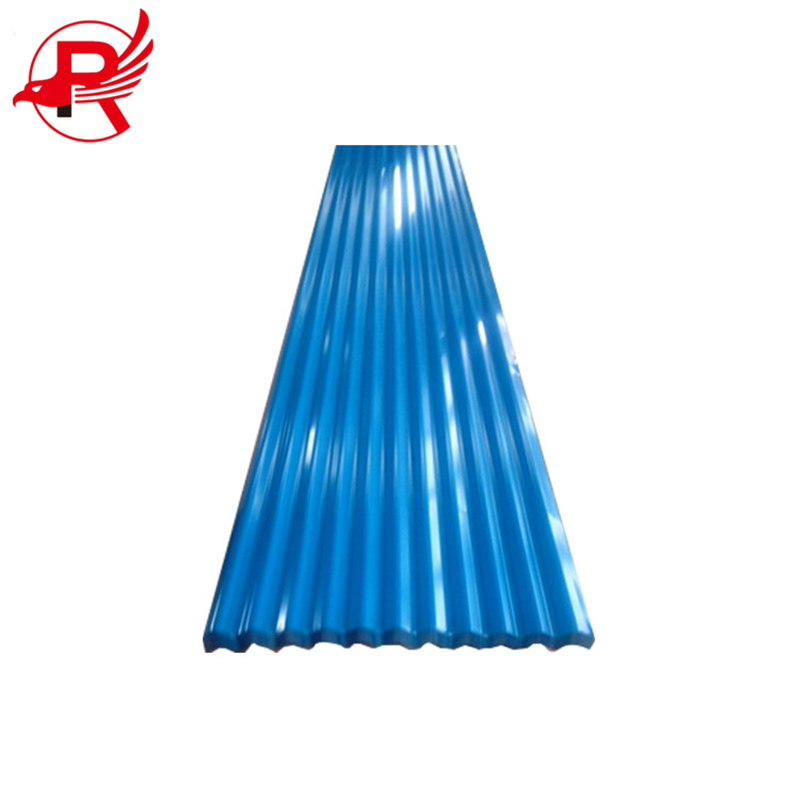

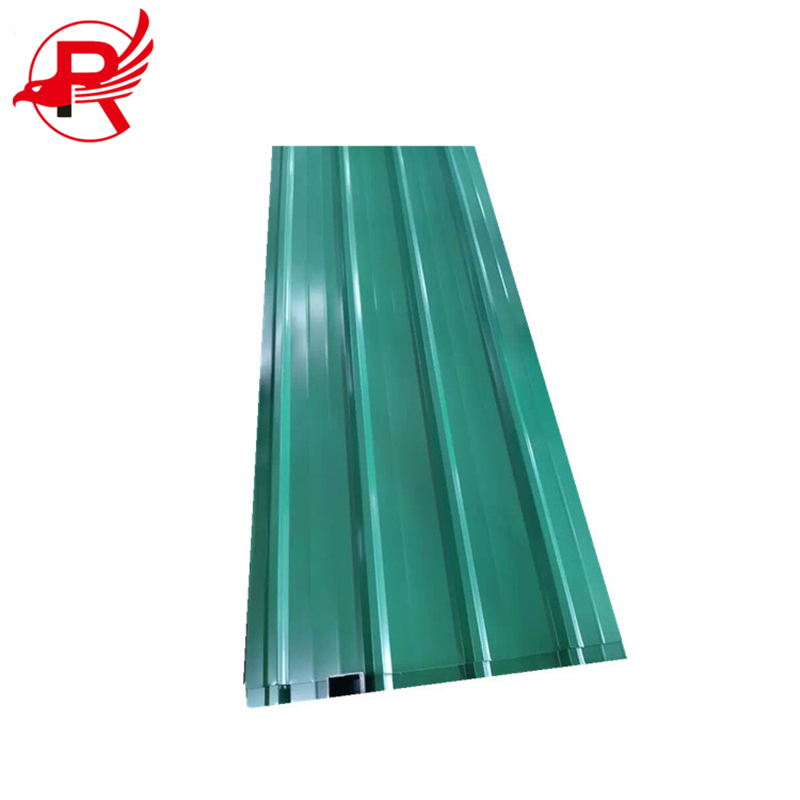

PriceList For Galvanized Steel H Beam - PPGI Per-Printed Galvanized Steel Sheet Color Coated Corrugated Roofing Plate – Royal Group

PriceList For Galvanized Steel H Beam - PPGI Per-Printed Galvanized Steel Sheet Color Coated Corrugated Roofing Plate – Royal Group Detail:

Product Detail

| STANDARD | AISI ASTM BS DIN GB JIS |

| GRADE | DX51D/52D/53D/54D+Z SGCC |

| THICKNESS RANGE(MM) | 0.12MM-3.0MM |

| STANDARD WIDTH(MM) | 960MM 1000MM 1100MM 1250MM 1500MM |

| LENGTH(MM) | 1M-6M |

Main Application

Steel structure house panel, movable house panel, etc.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Process of production

Next, I will introduce the performance of each link stage and the main features of process performance.

1. Color steel plate uncoiling

2. Color steel plate suture machine

3. The pressing roller corrects the concave and convex surface of the base plate to make the surface of the base plate flat.

4. The tensioning machine shall ensure that the steel plate runs smoothly without supporting the furnace bottom to avoid scratches.

5. Unwinding looper provides effective and sufficient time.

6. Alkali washing and degreasing can ensure the cleanness of the board surface, which is the basis for the subsequent painting process.

7. Cleaning prepares for the later work of product quality.

8. Bake to prepare for the first initial coating.

9. Initial painting

10. Dry to prepare for the next finishing coat.

11. Finish painting: this station is the last station to finish the main color of color steel plate finish paint, and complete the task according to customer requirements and production requirements.

12. Drying: After finishing painting, the product will enter the drying oven to complete the main process of the product.

13. The wind cooling temperature shall not exceed the winding temperature; 38 degrees.

14. The winding looper shall ensure the effective time for the winding down of the winder.

15. The winder shall meet the factory quality requirements of the industry.

16. The tensile force is the tensile force generated by tensioning the plates between various tensile forces.

17. Deviation rectifying machine

18. Purification shall be determined according to the customized requirements of the purchaser.

19. The manufacturer of digital inkjet printer can handle and judge the quality objection according to the inkjet information, which is easier to identify.

20. Plate surface cooling

21. Winder

22. The lifting scale is used to measure the weight of each finished roll.

23. Color steel plate packaging, warehousing and export finished products shall be stored vertically.

Packing and Transportation

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Our Customer

FAQ

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.

Product detail pictures:

Related Product Guide:

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for PriceList For Galvanized Steel H Beam - PPGI Per-Printed Galvanized Steel Sheet Color Coated Corrugated Roofing Plate – Royal Group , The product will supply to all over the world, such as: Spain, UK, Spain, Our company abides by the management idea of keep innovation, pursue excellence. On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.