Among many steel categories, H-beam is like a shining star, shining in the engineering field with its unique structure and superior performance. Next, let us explore the professional knowledge of steel and unveil its mysterious and practical veil. Today, we mainly talk about the difference and characteristics between H-beam and I-beam.

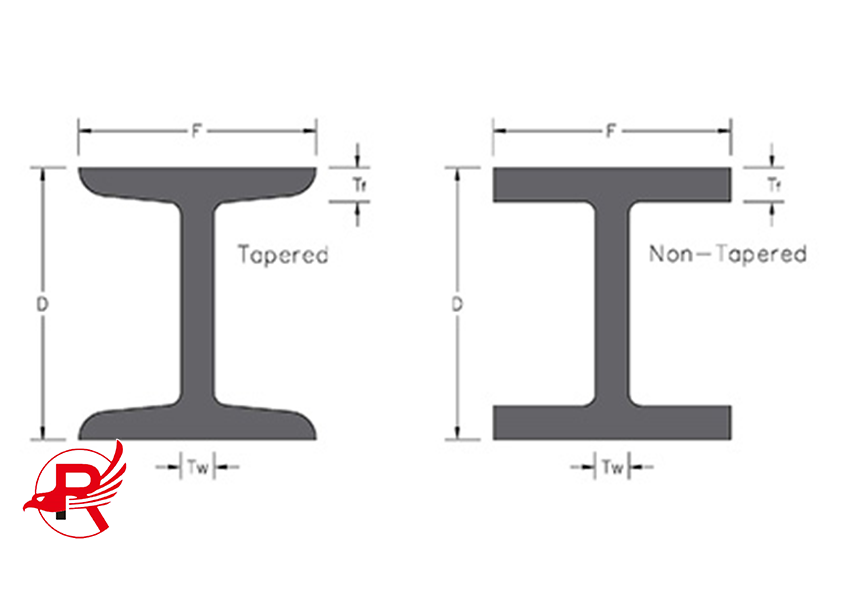

Cross-sectional Shape: The flange of H-beam is wide and the inner and outer sides are parallel, and the entire cross-sectional shape is regular, while the inner side of the flange of I-beam has a certain slope, usually inclined, which makes H-beam superior to I-beam in cross-sectional symmetry and uniformity.

Mechanical Properties: The section inertia moment and resistance moment of H-beam are relatively large in both main directions, and the force performance is more balanced. Whether it is subjected to axial pressure, tension or bending moment, it can show good stability and bearing capacity. I-beams have good unidirectional bending resistance, but are relatively weak in other directions, especially when subjected to bidirectional bending or torque, their performance is significantly inferior to H-beams.

Application Scenarios: Due to its superior mechanical properties, H-beams are widely used in large-scale building structures, bridge engineering, and heavy machinery manufacturing, which require high structural strength and stability. For example, in high-rise steel structures, H-beams, as the main load-bearing components, can effectively bear the vertical and horizontal loads of the building. I-beams are often used in some simple structures that have high unidirectional bending requirements and relatively low force requirements in other directions, such as beams of small buildings, light crane beams, etc.

Production Process: The production process of H-beams is relatively complex. Hot-rolled H-beams require special rolling mills and molds, and precise rolling processes are used to ensure the dimensional accuracy and parallelism of the flanges and webs. Welded H-beams require high welding technology and quality control to ensure the strength and quality of the welded parts. The production process of I-beam is relatively simple, and its production difficulty and cost are relatively low whether it is hot-rolled or cold-bent.

Processing Convenience: Since the flanges of H-beam are parallel, operations such as drilling, cutting, and welding are relatively easy during processing, and the processing accuracy is easier to ensure, which is conducive to improving construction efficiency and project quality. Since the flanges of I-beam have slopes, some processing operations are relatively inconvenient, and the dimensional accuracy and surface quality control after processing are more difficult.

In summary, H-beam and I-beam have their own characteristics and advantages in different aspects. In actual engineering applications, it is necessary to comprehensively consider factors such as specific engineering needs, structural design requirements, and cost to select the most suitable steel type.

Contact Us for More Information

Email: sales01@royalsteelgroup.com(Sales Director)

Tel / WhatsApp: +86 153 2001 6383

Post time: Feb-12-2025