MS Wire Rod / High Carbon Steel Wire Manufacturers / Steel Wire Price

|

Product name

|

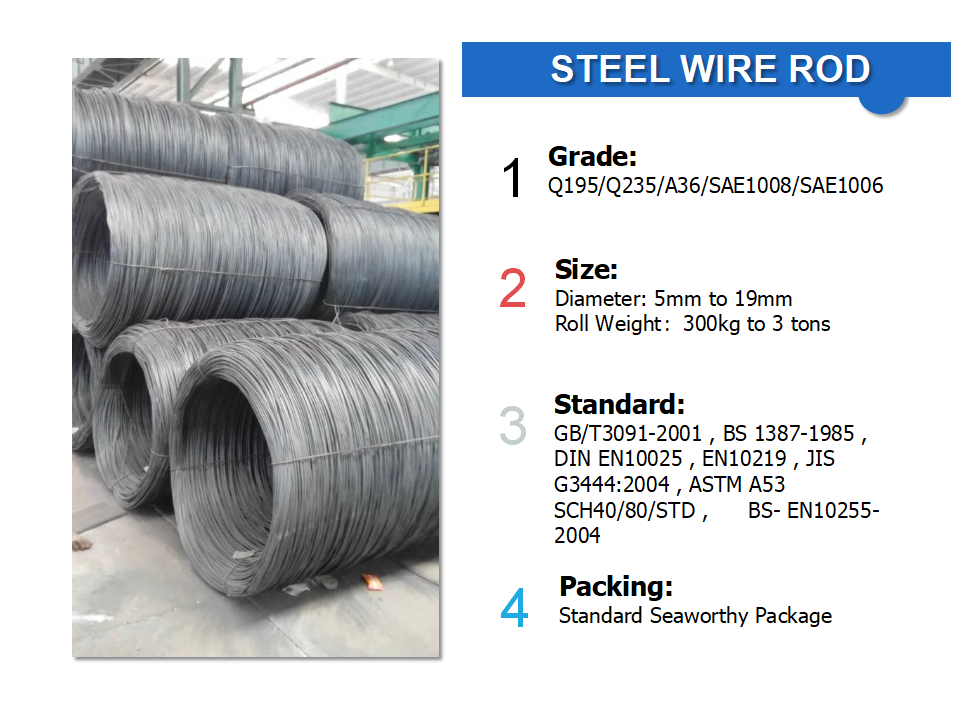

Steel wire rods / Carbon cutting steel wire rods

|

|

Material

|

Carbon steel

|

|

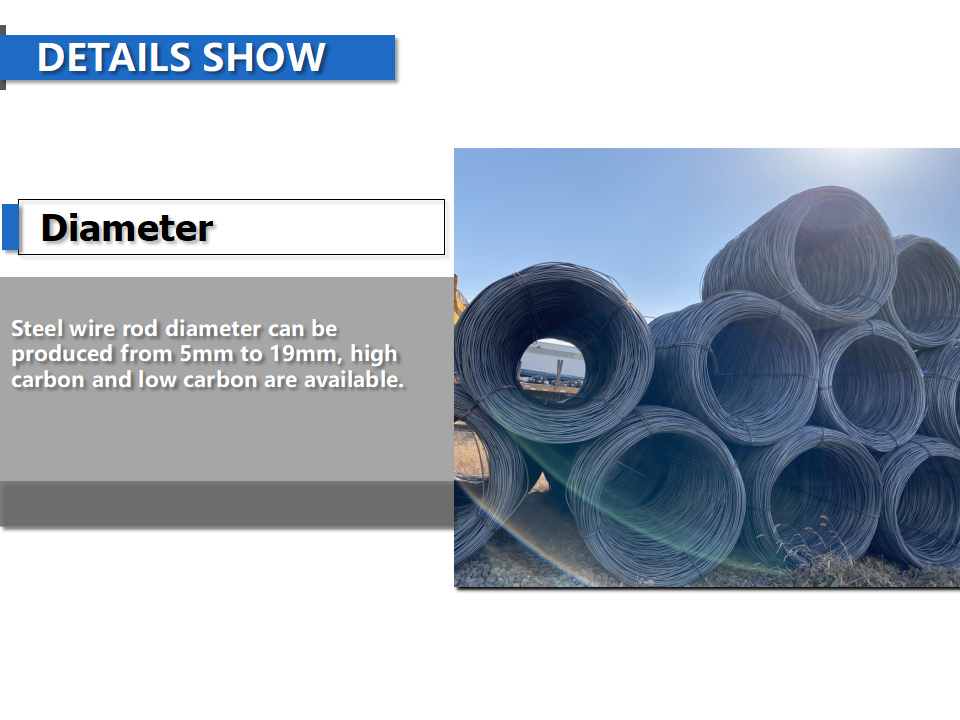

Diameter

|

5-20mm

|

|

Surface

|

Smooth

|

|

MoQ

|

1 ton

|

|

Certificate

|

ISO/SGS/CE/ENUL/GB/etc

|

Note:

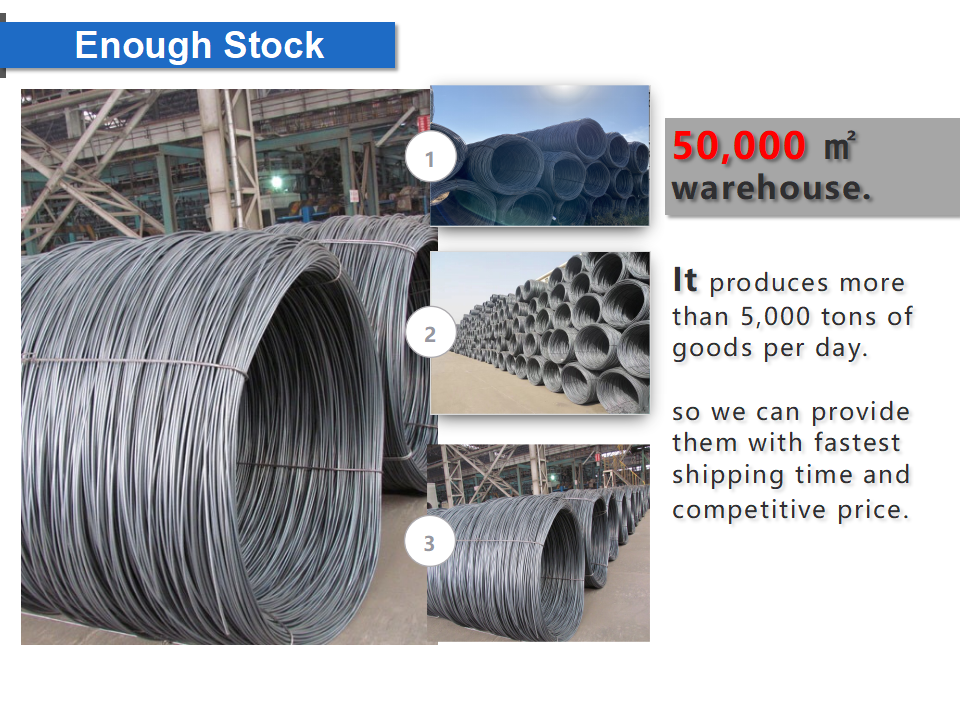

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

The wire rod production process typically involves the following steps:

Melting and refining: The production process begins with the melting of steel scrap or other raw materials in an electric arc furnace (EAF) or basic oxygen furnace (BOF). During this stage, impurities are removed to refine the steel composition.

Continuous casting: The molten steel is then cast into solid billets through a continuous casting machine. This process helps to create a continuous flow of steel billets without interruption.

Heating: The billets are heated in a reheating furnace to a temperature suitable for rolling. This heating process helps in reducing the force required for the subsequent rolling operations.

Rolling: The preheated billets are then passed through a series of rolling stands, typically in a hot rolling mill. The rolling process reduces the billet's cross-sectional area and increases its length, resulting in a wire rod with the desired dimensions. The number of rolling stands and the reduction percentage varies depending on the final wire rod size and desired properties.

Cooling: After rolling, the wire rod is cooled either through natural air cooling or water quenching to achieve the desired mechanical properties and microstructure.

Surface treatment: Depending on the specific requirements, the wire rod may undergo additional surface treatments like pickling or shot blasting to remove scale or impurities and improve the surface finish.

Coiling: The finished wire rod is then coiled into large coils for easy handling and transportation.

Testing and quality control: Samples are taken from the wire rod coils to perform various tests such as tensile strength, chemical analysis, and dimensional measurements. These tests ensure that the wire rod meets the desired quality standards and specifications.

Packaging and shipping: Once the wire rod coils pass the quality control checks, they are packed in suitable packaging materials, labeled, and prepared for shipping to customers.

Overall, wire rod production is a complex process that involves multiple stages to transform raw materials into high-quality wire rod products suitable for various industrial applications.

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Entertaining customer

We receive Chinese agents from customers all over the world to visit our company, every customer is full of confidence and trust in our enterprise.

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Daqiuzhuang Village, Tianjin City, China. Besides, we cooperate with many state-owned enterprises, such as BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP,etc.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.