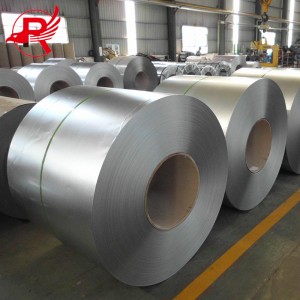

Low Price PCC Hot Dipped Zinc DX52D Cold Rolled Galvanized Steel Coil

Galvanized steel coil is a type of Cold Rolled Carbon Steel Coil that has undergone a galvanization process, which involves coating the steel with a layer of zinc to protect it from corrosion. Galvanized steel coils are commonly used in a wide range of applications, including:

1. Construction: Cold Rolled Stainless Steel Coils are used for roofing, walling, cladding, and structural framing. The coating of zinc makes the steel resistant to corrosion, which is essential for outdoor applications.

2. Automotive industry: Galvanized steel coils are used to manufacture parts for cars, trucks, and other vehicles. The durable and corrosion-resistant properties of these coils make them ideal for automotive applications.

3. Electrical industry: Cold Rolled Steel Coils are used to produce electrical panels and switchgear. The coating of zinc protects the steel from corrosion and makes it an ideal choice for electrical equipment that is exposed to harsh environments.

4. Agricultural industry: Galvanized steel coils are used to produce farm equipment, livestock enclosures, and other agricultural structures. The resistance to corrosion and durability of galvanized steel makes it suitable for outdoor applications in the agricultural industry.

5. Household appliances: Galvanized steel coils are used to produce a range of household appliances, including refrigerators, washing machines, and air conditioners. The coating of zinc makes the steel more resistant to rust and wear, extending the lifespan of these appliances.

Overall, galvanized steel coils are used in a wide range of industries and applications due to their durability, corrosion resistance, and versatility.

1. Corrosion Resistance: Galvanizing is an economical and effective rust prevention method that is often used. About half of the world's zinc production is used for this process. Zinc not only forms a dense protective layer on steel surface, but also has cathodic protection effect. When the zinc coating is damaged, it can still prevent the corrosion of iron based materials through cathodic protection.

2. Good Cold Bending and Welding Performance: low carbon steel is mainly used, which requires good cold bending, welding performance and certain stamping performance

3. Reflectivity: high reflectivity, making it a thermal barrier

4. The Coating Has Strong Toughness, and the zinc coating forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

|

Product Name

|

Hot Dipped Galvanized & Galvalume Steel Coil,Zinc Coated Steel ,GIHDGI,aluzinc Steel

|

|

Standard

|

EN10346, JIS G3302, ASTM A653,AS 1397,GB/T 2518,ASTM A792

|

|

Steel Grade

|

Dx51D, Dx52D, Dx53D, DX54D,DX55D,DX56D,DX57D, S220GD, S250GD, S280GD, S320GD,S350GD, S390GD,S420GD,S450GD,,S550GD,

SGHC, SGH340, SGH400, SGH440, SGH490,SGH540, SGCC,SGCH,SGCD1, SGCD2, SGCD3, SGCD4,SGC340, SGC400 , SGC440, SGC490,SGC570;

CS-A,CS-B,CS-C,Grade 33,grade 37.grade 40,garde 50,grade60,grade70,grade80

G1,G2,G3,G250,G300,G450,G550

As Requirement

|

|

Type

|

Coil/Sheet/Plate/Strip

|

|

Thickness

|

0.12mm-6.0mm or 0.8mm/1.0mm/1.2mm/1.5mm/2.0mm

|

|

Width

|

600mm-1800mm or 914mm/1000mm/1200mm/1219mm/1220mm/1524mm

|

|

Zinc Coating

|

Z30g/m2-Z600g/m2&AZ20-AZ220

|

|

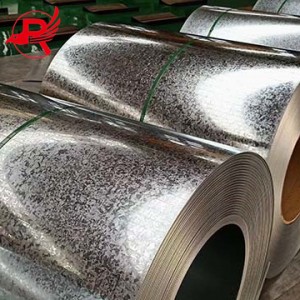

Surface Structure

|

Normal spangle (N),, spangle-free(FS),Zero Spangel

|

|

Surface Structure

|

Oiled (O),Passivated(C),Passivated and oiled (CO) ,Sealed (S),Phosphate (P),Phoaphte and oiled (CO)/AFP

|

|

Coil Weight

|

3 Tons -8Tons

|

|

Coil ID

|

508mm/610mm

|

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.