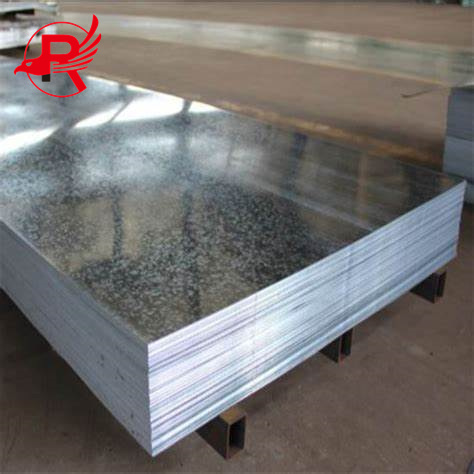

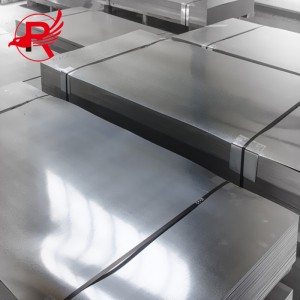

ASTM A653M-06a Galvanized Steel Sheet

Hot-rolled Galvanized sheet is a product in which a layer of zinc is coated on the surface of hot-rolled steel sheet. Hot-rolled galvanized sheets usually use the hot-dip galvanizing process, which is to immerse the hot-rolled Galvanized Steel Plate in molten zinc liquid to form a uniform and dense zinc layer. This treatment gives Hot Dip Galvanized Steel Plate excellent corrosion resistance, wear resistance and weather resistance. The production process of hot-rolled galvanized sheets includes multiple steps such as raw material preparation, zinc melt smelting, hot-dip galvanizing, and surface treatment. The characteristics of hot-rolled galvanized sheets include excellent corrosion resistance, wear resistance, good processing performance, smooth and beautiful surface, and good electrical conductivity. Hot-rolled galvanized sheets are widely used in construction, machinery, electricity, communications and other fields. They are often used in building structures, drainage systems, industrial equipment, agricultural machinery, transportation and other fields. Its corrosion resistance makes it one of the indispensable materials in various industries.

Hot-rolled galvanized sheets have several distinctive features that make them widely used in various fields. First of all, hot-rolled galvanized sheets have excellent corrosion resistance. The galvanized layer can effectively prevent the steel surface from being corroded by the atmosphere, water and chemical substances, thereby extending the service life of the steel. Secondly, hot-rolled galvanized sheets have good wear resistance and are suitable for environments that need to withstand friction and wear, such as building structures, mechanical equipment and other fields. In addition, hot-rolled galvanized sheets also have good processing properties and can be processed by bending, stamping, welding, etc., and are suitable for manufacturing various complex shapes. In addition, the surface of hot-rolled galvanized sheets is smooth and beautiful, and can be directly used as decorative materials. In addition, hot-rolled galvanized sheets also have good electrical conductivity and are suitable for electric power, communications and other fields. In general, hot-rolled galvanized sheet has become one of the indispensable materials in the fields of construction, machinery, electricity, communications and other fields due to its corrosion resistance, wear resistance and excellent processing performance.

Hot-rolled galvanized sheet is a product with a layer of zinc plated on the surface of hot-rolled steel sheet. It has excellent corrosion resistance and various characteristics. Therefore, it has a wide range of applications in various fields.

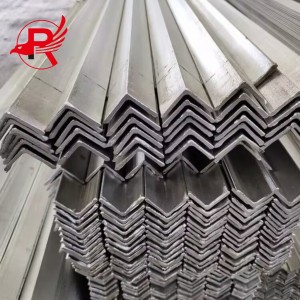

First of all, in the construction field, hot-rolled galvanized sheets are often used in the support and drainage systems of building structures. It can be used in building frames, stair handrails, railings and other components, and can also be used as the main material for drainage pipes because its corrosion resistance can effectively extend its service life.

Secondly, in the industrial field, hot-rolled galvanized sheets are often used to manufacture various equipment and components, such as storage tanks, pipelines, fans, conveying equipment, etc. The corrosion resistance of galvanized sheets enables long-term use in harsh industrial environments, ensuring the safe operation of equipment.

In addition, in the agricultural field, hot-rolled galvanized sheets also have important applications. It can be used in farm irrigation systems, support structures for agricultural machinery, etc. because its corrosion resistance can resist the erosion of equipment by chemicals in the soil.

In addition, in the field of transportation, hot-rolled galvanized sheets are also often used to manufacture automobile parts, ship components, etc., because their corrosion resistance can increase the service life of transportation vehicles.

In general, hot-rolled galvanized sheets have important applications in construction, industry, agriculture, transportation and other fields, and their corrosion resistance makes them one of the ideal materials for various equipment and structures.

|

Technical Standard

|

EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653

|

|

Steel Grade |

Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440,

SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement |

|

Thickness

|

customer's requirement

|

|

Width

|

according to customer's requirement

|

|

Type of Coating

|

Hot Dipped Galvanized Steel(HDGI)

|

|

Zinc Coating

|

30-275g/m2

|

|

Surface Treatment

|

Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U)

|

|

Surface Structure

|

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

|

|

Quality

|

Approved by SGS,ISO

|

|

ID

|

508mm/610mm

|

|

Coil Weight

|

3-20 metric ton per coil

|

|

Package |

Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by

seven steel belt.or according to customer's requirement |

|

Export market

|

Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc

|

| Gauge Thickness Comparison Table | ||||

| Gauge | Mild | Aluminum | Galvanized | Stainless |

| Gauge 3 | 6.08mm | 5.83mm | 6.35mm | |

| Gauge 4 | 5.7mm | 5.19mm | 5.95mm | |

| Gauge 5 | 5.32mm | 4.62mm | 5.55mm | |

| Gauge 6 | 4.94mm | 4.11mm | 5.16mm | |

| Gauge 7 | 4.56mm | 3.67mm | 4.76mm | |

| Gauge 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Gauge 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Gauge 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Gauge 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Gauge 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Gauge 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Gauge 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Gauge 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Gauge 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Gauge 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Gauge 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Gauge 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Gauge 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Gauge 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Gauge 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Gauge 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Gauge 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Gauge 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Gauge 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Gauge 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Gauge 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Gauge 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Gauge 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Gauge 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Gauge 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Gauge 33 | 0.22mm | 0.18mm | 0.24mm | |

| Gauge 34 | 0.20mm | 0.16mm | 0.22mm | |

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact

us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 5-20 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5. What kinds of payment methods do you accept?

30% in advance by T/T, 70% will be before shippment basic on FOB; 30% in advance by T/T, 70% against the copy of BL basic on CIF.