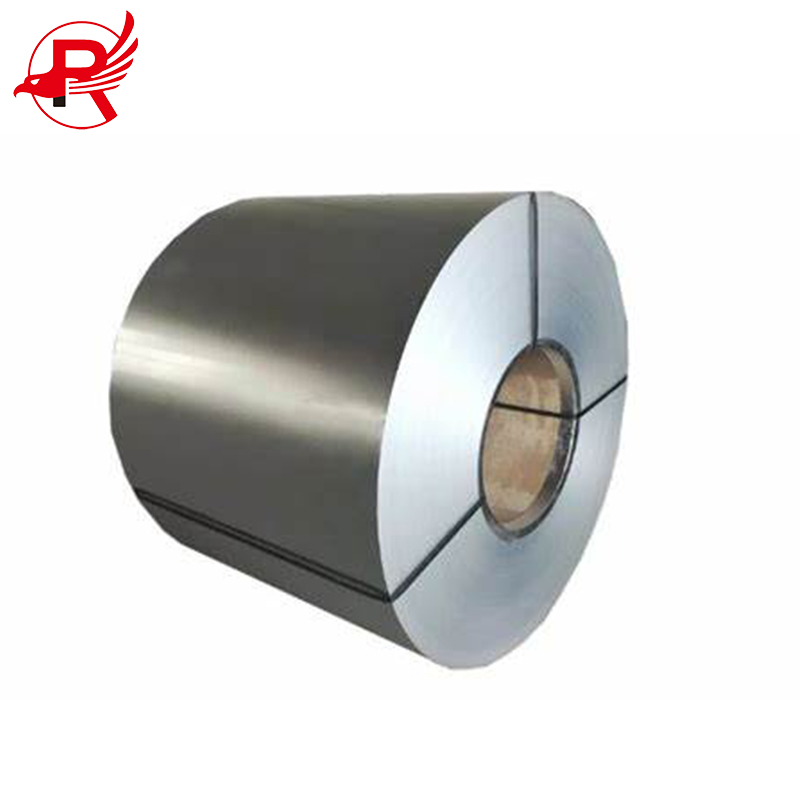

Hot Dipped A792 Aluzinc Galvalume Coil

| Product Name | DX51D AZ150 0.5mm thickness aluzinc/galvalume/zincalume Steel Coil |

| Material | DX51D/ 52D/ 53D/ 54D/ 55D/ DX56D+Z/ SGCC |

| Thickness Range | 0.15mm-3.0mm |

| Standard Width | 1000mm 1219mm 1250mm 1500mm 2000mm |

| Length | 1000mm 1500mm 2000mm |

| Coil Diameter | 508-610mm |

| Spangle | Regular,zero,minimized,big,skin pass |

| Weight per roll | 3-8ton |

Buildings: roofs, walls, garages, sound insulation walls, pipes, modular houses, etc

Automobile: muffler, exhaust pipe, wiper accessories, fuel tank, truck box, etc

Household appliances: refrigerator backplane, gas stove, air conditioner, electronic microwave oven, LCD frame, CRT explosion-proof belt, LED backlight, electrical cabinet

Agriculture: pig house, chicken house, granary, greenhouse pipes, etc

Others: heat insulation cover, heat exchanger, dryer, water heater and other chimney pipes, oven, illuminator and fluorescent lamp shade.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

The process flow of aluminum zinc plated sheet is divided into uncoiling process stage, coating process stage and winding process stage.

The production process of galvanized steel coil usually includes the following steps:

1. Steel preparation: The base material for galvanized steel coils is usually cold rolled steel that has been cleaned and pretreated to remove any residual oil or surface contamination.

2. Galvanizing: The coil is then immersed in a bath of molten zinc at a temperature of approximately 460°C. The zinc reacts with the steel to form a series of zinc-iron alloy layers that form a barrier that protects the steel from corrosion and other forms of wear.

3. Cooling: After the galvanizing process is complete, the coil is allowed to cool gradually in a controlled environment to prevent warping or other types of damage.

4. Tension Leveling: Once the coil has cooled, it passes through a series of rollers that apply tension and pressure to stretch and flatten the steel. This creates an even thickness and ensures a straight coil.

5. Cutting and Slitting: Finally, the galvanized steel coil is cut to the desired length and width and then slit into smaller coils as required. The coils can be further processed or turned into various products such as roofing shingles, pipes or wires.

Throughout the production process, we implement strict quality control measures to ensure that galvanized steel coils meet the required standards for strength, durability and corrosion resistance.

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China. Besides, we cooperate with many state-owned enterprises, such as BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP,etc.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.