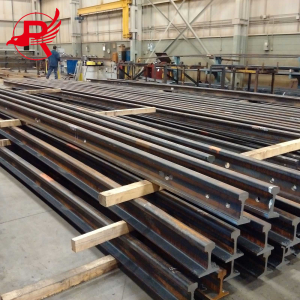

Heavy Industrial Rail Track Used Rail Steel Main Component of Railway Track and Track Circuit Q275 20Mnk Rail Steel

railroad rail are typically manufactured in standard lengths of 30 feet, 39 feet, or 60 feet, although longer rails can also be produced for specific projects. The most common type of steel rail used in railway tracks is known as flat-bottomed rail, which has a flat base and two angled sides. The weight of the rail, known as its "poundage," varies depending on the specific requirements of the railway line.

The production process of railroad track rail involves several steps, including:

- Raw material preparation: The production of railway steel begins with the selection and preparation of raw materials, typically high-quality steel billets. These billets are made from iron ore and other additives, such as limestone and coke, which are melted in a blast furnace to produce molten iron.

- Continuous casting: The molten iron is then transferred to a continuous casting machine, where it is poured into molds to form long continuous strands called billets. These billets are typically rectangular in shape and provide the starting material for the rail production process.

- Heating and rolling: The billets are reheated in a furnace to a temperature that allows them to be easily shaped and steel railroad track. They are then passed through a series of rolling mills, which exert tremendous pressure to shape the billets into the desired rail profile. The rolling process involves multiple repetitions of passing the billets through the rolling mills to gradually shape them into rails.

- Cooling and cutting: After the rolling process, the rails are cooled and cut to the required length. They are typically cut into standard lengths of 30 feet, 39 feet, or 60 feet, although longer rails can also be produced for specific projects.

- Inspection and treatment: The finished rails undergo rigorous inspection to ensure they meet industry standards and specifications. Various tests, such as dimensional measurements, chemical analysis, and mechanical testing, are conducted to verify the quality and integrity of the rails. Any defects or imperfections are identified and attended to.

- Surface treatment: To enhance the durability and corrosion resistance of the rails, they may undergo surface treatment processes. This can include applying protective coatings, such as anti-corrosion paint or galvanization, to prevent rust and corrosion, thereby extending the lifespan of the rails.

- Final inspection and packaging: Once the rails have been treated and pass the final inspection, they are carefully packaged for transportation to rail construction sites. The packaging is designed to protect the rails from any damage during transit.

Features

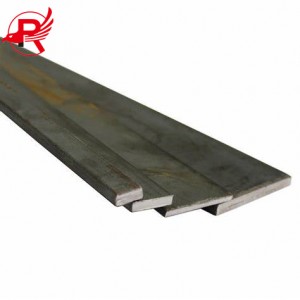

steel rails are an essential component of railway tracks and have several key features:

1. Strength and Durability: Steel rails are made from high-quality steel, which gives them excellent strength and durability. They are designed to withstand heavy loads, constant impacts, and extreme weather conditions without significant deformation or damage.

2. High Load-Bearing Capacity: Steel rails are engineered to support the weight of trains and their cargo. They can handle heavy loads and distribute the weight evenly, minimizing the risk of track failure or deformation.

3. Wear Resistance: Steel rails have a high resistance to wear and abrasion. This is important as trains constantly run on the rails, causing friction and wear over time. The steel used in rail production is specifically chosen for its ability to resist wear and maintain its shape over long periods of continuous use.

4. Dimensional Accuracy: Steel rails are manufactured to strict dimensional tolerances to ensure compatibility and smooth operation with other railway components, such as rail joints, cross ties, and fasteners. This allows for seamless movement of trains along the track and reduces the risk of derailments or disruptions.

5. Corrosion Resistance: Steel rails are often treated with protective coatings or undergo galvanization to enhance their resistance to corrosion. This is especially crucial in areas with high humidity, corrosive environments, or exposure to water, as corrosion can weaken the rails and compromise their structural integrity.

6. Longevity: Steel rails have a long service life, which contributes to the overall cost-effectiveness of railway infrastructure. With proper maintenance and periodic inspections, steel rails can last for several decades before needing to be replaced.

7. Standardization: Steel rails are manufactured according to industry standards and specifications set forth by organizations such as the American Society for Testing and Materials (ASTM) or the International Union of Railways (UIC). This ensures that steel rails from different manufacturers can be easily interchanged and integrated into existing rail systems.

Application

Steel rails are primarily used for the construction of railway tracks, allowing trains to transport passengers and goods efficiently. However, they have several other applications as well:

1. Tram and Light Rail Systems: Steel rails are used in tram and light rail systems to guide the wheels of the vehicles along a designated path. These systems are commonly found in urban areas and provide transportation within cities and towns.

2. Industrial and Mining Tracks: Steel rails are used in industrial settings, such as factories or mining sites, to support the transportation of heavy equipment and materials. They are often laid within warehouses or yards, connecting different workstations or storage areas.

3. Port and Terminal Tracks: Steel rails are used in ports and terminals to facilitate the movement of cargo. They are laid out on docks or within storage areas to enable the loading and unloading of ships and containers.

4. Theme Parks and Roller Coasters: Steel rails are an integral part of roller coasters and other amusement park rides. They provide the structure and foundation for the track, ensuring the safety and smooth operation of the rides.

5. Conveyor Systems: Steel rails can be used in conveyor systems, which are used in various industries to transport goods or materials along a fixed path. They provide a sturdy and reliable track for the conveyor belts to run on.

6. Temporary Tracks: Steel rails can be used as temporary tracks in construction sites or during maintenance projects. They allow for the movement of heavy machinery and equipment, ensuring efficient operations without causing damage to the underlying ground.

Parameters

|

Grade

|

700/900A/1100

|

|

Rail Heigth

|

95mm or Customer's requirements

|

|

Bottom Width

|

200mm or Customer's requirements

|

|

Web Thickness

|

60mm or Customer's requirements

|

|

Usage

|

Railway Mining,Architectural decoration,Structural pipe making, Gantry Crane, Train

|

|

Secondary Or Not

|

Non-secondary

|

|

Tolerance

|

±1%

|

|

Delivery Time

|

15-21 days

|

|

Length

|

10-12m or Customer's requirements

|

|

Payment Term

|

T/T 30% Deposit

|

Details

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact

us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 5-20 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5. What kinds of payment methods do you accept?

30% in advance by T/T, 70% will be before shippment basic on FOB; 30% in advance by T/T, 70% against the copy of BL basic on CIF.