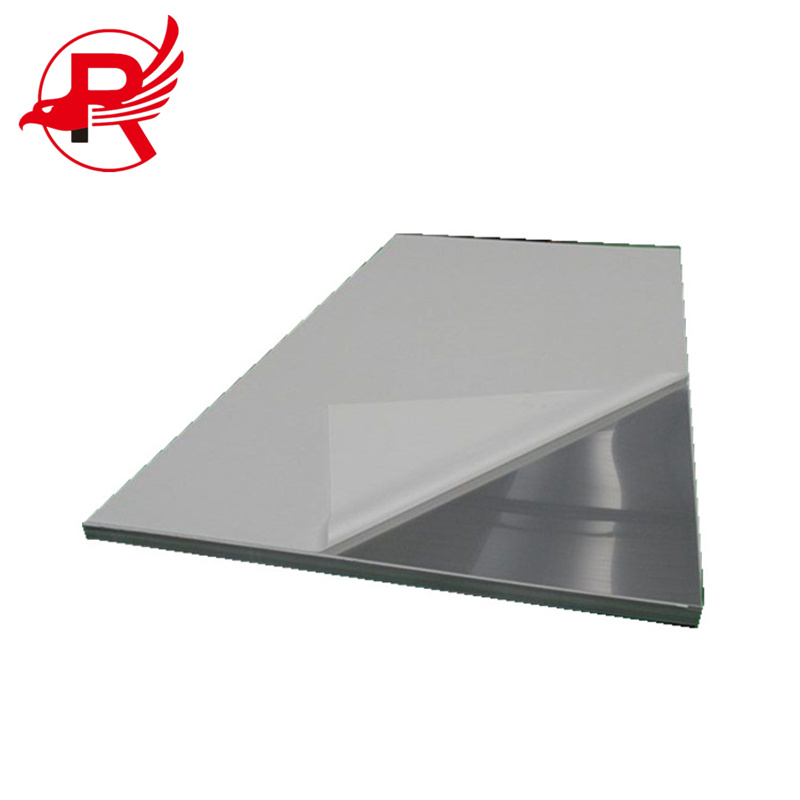

High Quality Z275 DX51D Gi Cold Rolled Galvanized Carbon Steel Sheet

Galvanized sheet refers to a steel sheet coated with a layer of zinc on the surface. Galvanizing is an economical and effective rust prevention method that is often used, and about half of the world's zinc production is used in this process.

According to the production and processing methods, it can be divided into the following categories:

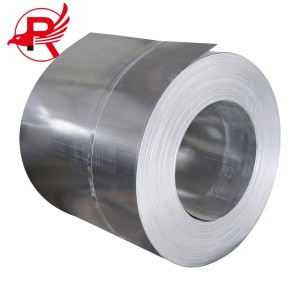

Galvanized Steel Sheet. Dip the thin steel plate into the molten zinc tank to make the thin steel plate with a layer of zinc adhered to its surface. At present, the continuous galvanizing process is mainly used for production, that is, the coiled steel plate is continuously immersed in a galvanizing tank with molten zinc to make a galvanized steel plate;

Alloyed galvanized steel plate. This kind of steel panel is also made by hot dip method, but it is heated to about 500℃ immediately after coming out of the tank, so that it can form an alloy film of zinc and iron. This galvanized sheet has good paint adhesion and weldability;

Electro-galvanized steel plate. The galvanized steel panel manufactured by electroplating has good processability. However, the coating is thinner and its corrosion resistance is not as good as that of hot-dip galvanized sheets

1. Corrosion resistance, paintability, formability and spot weldability.

2. It has a wide range of uses, mainly used for parts of small household appliances that require good appearance, but it is more expensive than SECC, so many manufacturers switch to SECC to save costs.

3. Divided by zinc: the size of the spangle and the thickness of the zinc layer can indicate the quality of the galvanizing, the smaller and thicker the better. Manufacturers can also add anti-fingerprint treatment. In addition, it can be distinguished by its coating, such as Z12, which means that the total amount of coating on both sides is 120g/mm.

Hot Dip Galvanized Steel Plate and strip steel products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commercial industries. Among them, the construction industry is mainly used to manufacture anti-corrosion industrial and civil building roof panels, roof grids, etc.; the light industry industry uses it to manufacture home appliance shells, civil chimneys, kitchen utensils, etc., and the automobile industry is mainly used to manufacture corrosion-resistant parts of cars, etc. ; Agriculture, animal husbandry and fishery are mainly used for grain storage and transportation, frozen meat and aquatic products, etc.; commercial is mainly used for storage and transportation of materials, packaging equipment, etc.

|

Technical Standard

|

EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653

|

|

Steel Grade |

Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440,

SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement |

|

Thickness

|

customer's requirement

|

|

Width

|

according to customer's requirement

|

|

Type of Coating

|

Hot Dipped Galvanized Steel(HDGI)

|

|

Zinc Coating

|

30-275g/m2

|

|

Surface Treatment

|

Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U)

|

|

Surface Structure

|

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

|

|

Quality

|

Approved by SGS,ISO

|

|

ID

|

508mm/610mm

|

|

Coil Weight

|

3-20 metric ton per coil

|

|

Package |

Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by

seven steel belt.or according to customer's requirement |

|

Export market

|

Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc

|

| Gauge Thickness Comparison Table | ||||

| Gauge | Mild | Aluminum | Galvanized | Stainless |

| Gauge 3 | 6.08mm | 5.83mm | 6.35mm | |

| Gauge 4 | 5.7mm | 5.19mm | 5.95mm | |

| Gauge 5 | 5.32mm | 4.62mm | 5.55mm | |

| Gauge 6 | 4.94mm | 4.11mm | 5.16mm | |

| Gauge 7 | 4.56mm | 3.67mm | 4.76mm | |

| Gauge 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Gauge 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Gauge 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Gauge 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Gauge 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Gauge 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Gauge 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Gauge 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Gauge 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Gauge 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Gauge 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Gauge 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Gauge 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Gauge 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Gauge 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Gauge 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Gauge 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Gauge 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Gauge 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Gauge 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Gauge 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Gauge 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Gauge 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Gauge 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Gauge 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Gauge 33 | 0.22mm | 0.18mm | 0.24mm | |

| Gauge 34 | 0.20mm | 0.16mm | 0.22mm | |

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact

us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 5-20 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5. What kinds of payment methods do you accept?

30% in advance by T/T, 70% will be before shippment basic on FOB; 30% in advance by T/T, 70% against the copy of BL basic on CIF.