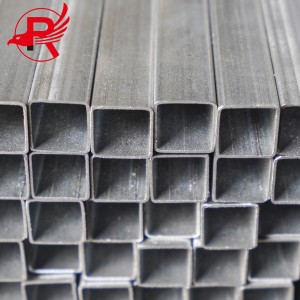

Factory Price Square Pipe Black Galvanized Steel Pipe

Galvanized pipe, also known as galvanized steel pipe, is divided into two types: hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing has a thick zinc layer and has the advantages of uniform coating, strong adhesion, and long service life.

Galvanized pipe, also known as galvanized steel pipe, is divided into two types: hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing has a thick zinc layer and has the advantages of uniform coating, strong adhesion, and long service life. The cost of electro-galvanized pipes is low, the surface is not very smooth, and its corrosion resistance is much worse than that of hot-dip galvanized pipes.

Application

Hot-dip galvanizing pipe reacts molten metal with an iron matrix to produce an alloy layer, thereby combining the matrix and the coating. Hot-dip galvanizing is to pickle the steel pipe first. In order to remove the iron oxide on the surface of the steel pipe, after pickling, it is cleaned in an aqueous solution of ammonium chloride or zinc chloride or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to in a hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion, and long service life. Most of the processes in the north adopt the zinc-replenishing process of direct coiling of galvanized strips.

|

Product Name

|

Galvanized Square Steel Pipe

|

|||

|

Zinc Coating

|

35μm-200μm

|

|||

|

Wall Thickness

|

1-5MM

|

|||

|

Surface

|

Pre-galvanized, Hot dipped galvanized, Electro galvanized, Black, Painted, Threaded, Engraved, Socket.

|

|||

|

Grade

|

Q235, Q345, S235JR, S275JR, STK400, STK500, S355JR, GR.B-D

|

|||

|

Tolerance

|

±1%

|

|||

|

Oiled or Non-Oiled

|

Non-Oiled

|

|||

|

Delivery Time

|

3-15 days (according to the actual tonnage) | |||

|

Usage

|

Civil engineering, architecture, steel towers, shipyard, scaffoldings, struts, piles for suppression of landslide and other

structures |

|||

|

Package

|

In bundles with steel strip or in loose, non-woven fabrics packings or as per customers' request

|

|||

|

MOQ

|

1 ton

|

|||

|

Payment Term

|

T/T LC DP

|

|||

|

Trade Term

|

FOB,CFR,CIF ,DDP,EXW

|

|||

Details

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact

us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 5-20 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5. What kinds of payment methods do you accept?

30% in advance by T/T, 70% will be before shippment basic on FOB; 30% in advance by T/T, 70% against the copy of BL basic on CIF.