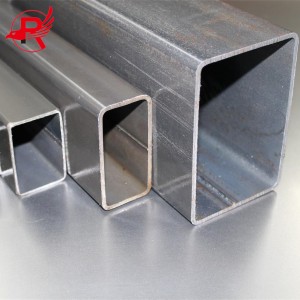

A36 Erw Welded Hot Rolled Black Carbon Steel Pipe Tube

|

Product Name |

Erw Carbon Steel Rectangular pipe |

|

Material |

Q195 = S195 / A53 Grade A Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2 Q345 = S355JR / A500 Grade B Grade C 10#,20#,45#,Q235,Q345,Q195,Q215,Q345C,Q345A

16Mn,Q345B,T1,T2,T5,T9,T11,T12,T22,T91,T92,P1,P2,P5,P9,P11,P12,P22,P91,P92,

15CrMO,Cr5Mo,10CrMo910,12CrMo,13CrMo44,30CrMo,A333 GR.1,GR.3,GR.6,GR.7,etc

SAE 1050-1065

|

|

Wall Thickness |

4.5MM~60MM |

|

Color |

Clean, blasting and painting or as required |

| Technique | Hot rolled/Cold rolled |

|

Used |

Shock absorber,Motorcycle accessories,drill pipe,Excavator accessories,Auto part,hight pressure boiler tube, honed tube,Transmission shaftetc |

|

Section Shape |

Rectangular |

|

Packing |

Bundle, or with all kinds of colors PVC or as your requirements |

|

MOQ |

5 Tons, more quantity price will be lower |

|

Origin |

Tianjin China |

|

Certificates |

ISO9001-2008,SGS.BV,TUV |

|

Delivery Time |

Usually within 10-45 days after receipt of advance payment |

Carbon Steel Rectangular Pipe is an iron-carbon alloy with a carbon content of 0.0218% to 2.11%. Also called carbon steel. Generally also contain a small amount of silicon, manganese, sulfur, phosphorus. Generally, the higher the carbon content in carbon steel, the greater the hardness and the higher the strength, but the lower the plasticity.

The rectangular pipe is widely used in construction, machinery, shipbuilding, electric power, agriculture and animal husbandry, storage, fire protection, home appliances and other industries, and can be said to be an indispensable steel for modern industrial development.

Note:

1. Free sampling, 100% after-sales quality assurance, and support for any payment method;

2. All other specifications of carbon steel pipes can be provided according to your requirements (OEM and ODM)! You will get the ex factory price from Royal Group.

3. Professional product inspection service, high customer satisfaction.

4. The production cycle is short, and 80% of orders will be delivered in advance.

5. The drawings are confidential and all are for the purpose of customers.

1. Requirements: documents or drawings

2. Merchant confirmation: product style confirmation

3. Confirm customization: confirm payment time and production time (pay deposit)

4. Production on demand: waiting for receipt confirmation

5. Confirm delivery: pay the balance and deliver

6. Confirm receipt

The production process of square welded steel pipes usually includes the following main steps, and the specific process may be adjusted depending on the production equipment and product specifications:

1. Raw Material Preparation

Steel strip selection: Use hot-rolled or cold-rolled steel strip as raw material, and select the appropriate steel strip material (such as carbon steel, alloy steel, etc.) according to the product specifications (such as wall thickness, size).

Uncoiling and leveling: Unroll the coiled steel strip through the uncoiling machine, and use the leveling machine to eliminate the wave shape or bending of the steel strip to ensure the surface flatness.

2. Forming

Pre-bending and rough forming: The steel strip is gradually bent by multiple sets of rollers to form a preliminary rectangular profile. Usually "cold bending forming" technology is used to avoid material hardening.

Fine forming: Use precision molds to further adjust the shape to ensure the dimensional accuracy of the square steel pipe (such as side length, verticality).

3. Welding

High-frequency resistance welding (ERW):

Align the edges of the formed steel strip and heat the edges of the steel strip to a molten state through a high-frequency current.

Apply pressure to fuse the edges to form a continuous weld.

Submerged Arc Welding (SAW):

Applicable to large-diameter or thick-walled steel pipes, flux is covered at the weld, and the welding wire and the base material are melted by the arc to form a weld.

4. Weld Processing

Deburring: Use a milling cutter or grinding wheel to remove burrs on the inner and outer surfaces of the weld to ensure a smooth surface.

Weld flaw detection: Use ultrasound or X-ray to detect internal defects in the weld (such as pores and lack of fusion).

5. Sizing and Straightening

Sizing machine: Adjust the dimensional accuracy of the steel pipe by rolling to ensure that the side length and roundness meet the standards.

Straightening machine: Eliminate the bending deformation of the steel pipe during the forming or welding process.

6. Cooling and Cutting

Cooling: Use water cooling or air cooling to reduce the temperature of the steel pipe to avoid thermal deformation.

Cutting: Use a flying saw or a circular saw to cut the continuous steel pipe into the required length (such as 6 meters, 12 meters).

7. Surface Treatment

Pickling/phosphating: remove surface oxide scale and impurities to prepare for subsequent treatment.

Galvanizing or painting: improve the corrosion resistance of steel pipes by hot-dip galvanizing or spraying anti-rust paint.

8. Quality Inspection

Dimension measurement: check parameters such as side length, wall thickness, length, etc.

Mechanical property testing: tensile test, impact test, etc. to verify material strength and toughness.

Appearance inspection: visually or through automated equipment to detect surface defects (such as scratches, dents).

9. Packaging and Storage

Packaging: bundle, label, or use moisture-proof materials for packaging according to customer needs.

Storage: store in categories to avoid deformation or rust caused by heavy pressure or humid environment.

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Precautions for packaging and transportation of carbon steel pipes

1. Carbon steel pipes must be protected from damage caused by collision, extrusion and cuts during transportation, storage and use.

2. When using A36 Steel Pipe, you should follow the corresponding safety operating procedures and pay attention to prevent explosions, fires, poisoning and other accidents.

3. During use, carbon steel pipes should avoid contact with high temperatures, corrosive media, etc. If used in these environments, carbon steel pipes made of special materials such as high temperature resistance and corrosion resistance should be selected.

4. When selecting A53 Steel Pipe, carbon steel pipes of suitable materials and specifications should be selected based on comprehensive considerations such as the use environment, medium properties, pressure, temperature and other factors.

5. Before carbon steel pipes are used, necessary inspections and tests should be carried out to ensure that their quality meets the requirements.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Services

We Specialize In Custom Material Processing.

Our experienced team will cut, shape and weld materials to your specifications. We are a one-stop-shop: Order the products you need, have them customized to your specifications, and get fast, free delivery. Our goal is to minimize work for you—saving you time and money.

Sawing, Shearing & Flame Cutting

We have three bandsaws on site that are capable of miter cutting. We flame cut plate ⅜" thick through 4½", and our Cincinnati Shear is capable of cutting sheet as thin as 22 gauge and as heavy as ¼” square and accurate. If you need materials cut quickly and accurately, we offer same-day service.

Welding

Our Lincoln 255 MIG Welding Machine allows our experienced welders to weld any kind of house columns or miscellaneous metals that you require.

Hole Punching

We specialize in steel flitch plates. Our team can produce holes as small as ⅛" diameter and as large as 4¼" diameter. We have Hougen and Milwaukee magnetic drill presses, manual punches and ironworkers, and automatic CNC punches and drill presses.

Subcontracting

If necessary, we will work with one of our many partners from around the country to deliver you a premium, cost-effective product. Our partnerships ensure that your order is efficiently handled by the most experienced professionals in the industry.

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Daqiuzhuang Village, Tianjin City, China. Besides, we cooperate with many state-owned enterprises, such as BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP,etc.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.