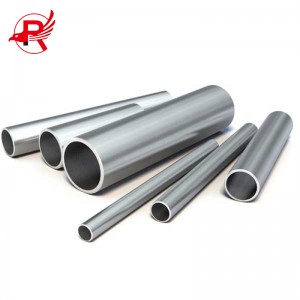

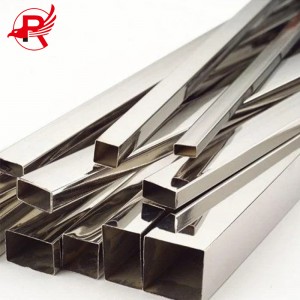

Decorative Welded Round SS Tube SUS 304L 316 316L 304 Stainless Steel Pipe / Tube

| Product Name | Stainless steel Round pipe |

| Standard | ASTM AISI DIN, EN, GB, JIS |

| Steel Grade

|

200 Series: 201,202 |

| 300 Series: 301,304,304L,316,316L,316Ti,317L,321,309s,310s | |

| 400 Series: 409L,410,410s,420j1,420j2,430,444,441,436 | |

| Duplex Steel: 904L,2205,2507,2101,2520,2304 | |

| Outer Diameter | 6-2500mm(as required) |

| Thickness | 0.3mm-150mm (as required) |

| Length | 2000mm/2500mm/3000mm/6000mm/12000mm(as required) |

| Technique | Seamless |

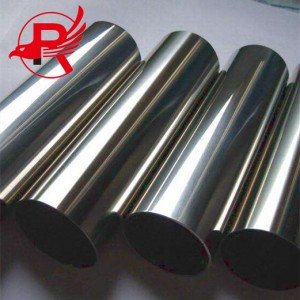

| Surface | No.1 2B BA 6K 8K Mirror No.4 HL |

| Tolerance | ±1% |

| Price Terms | FOB,CFR,CIF |

Stainless steel pipe is a kind of hollow long round steel, which is mainly used in industrial transportation pipelines such as petroleum, chemical industry, medical treatment, food, light industry, mechanical instrument, etc., as well as mechanical structural components. In addition, when the bending and torsional strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. Also commonly used as furniture and kitchenware, etc.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Stainless Steel Pipe Chemical Compositions

|

Chemical Composition %

|

||||||||

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

|

201

|

≤0 .15

|

≤0 .75

|

5. 5-7. 5

|

≤0.06

|

≤ 0.03

|

3.5 -5.5

|

16 .0 -18.0

|

-

|

|

202

|

≤0 .15

|

≤l.0

|

7.5-10.0

|

≤0.06

|

≤ 0.03

|

4.0-6.0

|

17.0-19.0

|

-

|

|

301

|

≤0 .15

|

≤l.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

6.0-8.0

|

16.0-18.0

|

-

|

|

302

|

≤0 .15

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

8.0-10.0

|

17.0-19.0

|

-

|

|

304

|

≤0 .0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

8.0-10.5

|

18.0-20.0

|

-

|

|

304L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0-13.0

|

18.0-20.0

|

-

|

|

309S

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0-15.0

|

22.0-24.0

|

-

|

|

310S

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.035

|

≤ 0.03

|

19.0-22.0

|

24.0-26.0

|

|

|

316

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

10.0-14.0

|

16.0-18.0

|

2.0-3.0

|

|

316L

|

≤0 .03

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0 - 15.0

|

16 .0 -1 8.0

|

2.0 -3.0

|

|

321

|

≤ 0 .08

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0 - 13 .0

|

17.0 -1 9.0

|

-

|

|

630

|

≤ 0 .07

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

3.0-5.0

|

15.5-17.5

|

-

|

|

631

|

≤0.09

|

≤1.0

|

≤1.0

|

≤0.030

|

≤0.035

|

6.50-7.75

|

16.0-18.0

|

-

|

|

904L

|

≤ 2 .0

|

≤0.045

|

≤1.0

|

≤0.035

|

-

|

23.0·28.0

|

19.0-23.0

|

4.0-5.0

|

|

2205

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.030

|

≤0.02

|

4.5-6.5

|

22.0-23.0

|

3.0-3.5

|

|

2507

|

≤0.03

|

≤0.8

|

≤1.2

|

≤0.035

|

≤0.02

|

6.0-8.0

|

24.0-26.0

|

3.0-5.0

|

|

2520

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.045

|

≤ 0.03

|

0.19 -0. 22

|

0. 24 -0 . 26

|

-

|

|

410

|

≤0.15

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

-

|

11.5-13.5

|

-

|

|

430

|

≤0.1 2

|

≤0.75

|

≤1.0

|

≤ 0.040

|

≤ 0.03

|

≤0.60

|

16.0 -18.0

|

|

Through different processing methods of cold rolling and surface reprocessing after rolling, the surface finish of stainless steel bars can have different types.

The quality of the stainless steel surface is critical as it directly affects its corrosion resistance. Corrosion is a natural phenomenon that occurs when metals react with the chemical environment around them, such as air or moisture.

With stainless steel, the chromium in the alloy forms a protective layer on the surface that prevents the metal from reacting with its surroundings. This layer is called a passivation film. However, the passive film on stainless steel is not indestructible. If the surface is damaged or contaminated, the film can rupture, leaving the metal vulnerable to corrosion. That's why maintaining the cleanliness and integrity of stainless steel surfaces is critical.

There are several ways to improve the quality of stainless steel surfaces. One way is to use a process called passivation. This involves treating the surface with a special solution that removes any impurities and enhances the protective properties of the passive film. Passivation can be accomplished by a variety of techniques such as chemical baths or electropolishing.

Another way to maintain the quality of stainless steel surfaces is regular cleaning and maintenance. Stainless steel surfaces should be cleaned with a mild detergent and a soft cloth, and any stubborn stains or discolorations can be removed with specialized cleaning products.

Overall, the importance of the stainless steel finish cannot be overemphasized. Surface quality is critical to ensure the durability and longevity of the material. By following proper cleaning and maintenance procedures, stainless steel can continue to provide optimum performance and aesthetic appeal for many years to come.

Stainless steel is known for its durability, corrosion resistance and versatility. It is commonly used in various applications including pipe production.

Stainless steel pipe is widely used in industrial settings and in the construction of buildings and structures. The production process of stainless steel pipe is a complex process involving multiple steps.

Raw Material

The first step in manufacturing stainless steel pipe is to obtain raw materials. The main component of stainless steel is iron, but it is combined with other materials to give it unique properties. These materials include nickel, chromium and molybdenum. Raw materials are carefully selected and combined in proportion to produce the desired grade of stainless steel. These components are then melted together in a high-temperature furnace, where they fuse to form an alloy.casting Once the alloy is formed, it is poured into a mold to begin the process of shaping the material. Molds, usually made of sand or ceramic, are designed to form hollow tubes at the end of the process. After the alloy is poured into the mold, it is allowed to cool and solidify. The final shape is a tube with rough edges and an uneven surface.

scroll

The next step in the process is rolling. The tube is fed through a series of rollers that compress and shape the material, resulting in a more even surface and consistent diameter. The tube is then passed through the mandrel to ensure it is perfectly round and the wall thickness is uniform. This process, known as sizing, is critical to ensuring that the finished product meets the required specifications.

Cutting and Finishing

Once the tube has been sized, it's time for cutting and finishing. This includes cutting the tube to the desired length and smoothing out any rough edges or burrs. The tube is then polished to give it a smooth, shiny finish. This process helps to increase the pipe's corrosion resistance and gives it an attractive appearance.

Testing and Inspection

Finished products must undergo rigorous testing and inspection before they are sold. Check the tube for any defects such as cracks or rust spots. It also passed tests for strength, durability and corrosion resistance. Once the pipe has passed all required tests and inspections, it is ready for use. Stainless steel pipe produced using this process is used in a range of industries, including construction, oil and gas, and manufacturing.

In summary, the production of stainless steel pipes is a complex multi-step process involving multiple stages from raw materials to finished products. It requires careful attention to detail, precision and quality control to ensure the finished product meets the required specifications and is suitable for a variety of applications.

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Our Customer

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.