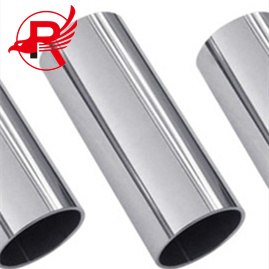

China Supplier ASTM Heat-resistant 309 310 310S Stainless Steel Tube

|

tem

|

309 310 310S Stainless Steel Pipe |

|

Standard

|

JIS, AiSi, ASTM, GB, DIN, EN

|

|

Place of Origin

|

China

|

|

Brand Name

|

ROYAL

|

|

Type

|

Seamless / welded

|

|

Application

|

Chemical industry, mechanical equipment

|

|

Processing Service

|

Bending, Welding, Decoiling, Punching, Cutting, Moulding

|

|

Technique

|

Hot rolled/cold rolled

|

|

Payment terms

|

L/C T/T (30%DEPOSIT)

|

|

Price Term

|

CIF CFR FOB EX-WORK

|

Features

High temperature resistance: It can remain stable at extremely high temperatures and is suitable for high temperature environments. For example, some heat-resistant stainless steel plates can withstand temperatures of 1035℃ and above.

Corrosion resistance: It has excellent corrosion resistance and is not easily corroded or damaged in various strong acids, strong alkalis and high-temperature corrosive media. It can work stably in corrosive environments such as chemical industry and energy.

High mechanical strength: It can still maintain good mechanical properties in high temperature environments, such as high strength, high hardness, high wear resistance, etc., and can withstand pressure and stress under high temperature.

Low thermal expansion coefficient: Small deformation in high temperature environments, ensuring the stability of the structure and reducing deformation and stress concentration caused by temperature changes.

Good oxidation resistance: It is not easy to oxidize and ablate at high temperatures, and can be used in high-temperature oxidizing atmospheres for a long time, extending the service life of the equipment.

Good processing performance: It can be processed by various processing methods such as welding, cutting, stamping, cold forming and hot extrusion, and is easy to process into various shapes and sizes to meet the manufacturing needs of different fields.

Common models and performance

0Cr25Ni20 (310S): also known as 2520, the nickel content is between 19%-22%, can withstand heating at 1035℃, is a stainless steel SUS316 solid solution liner material, commonly used in furnace materials, automobile purification device materials, etc.

2Cr25Ni20: can withstand repeated heating below 1035℃, belongs to oxidation-resistant steel, used for furnace parts, nozzles, combustion chambers, etc.

1Cr16Ni35: good resistance to carburization and nitriding, can be repeatedly heated below 1035℃, mainly used for furnace steel.

2Cr25N: strong resistance to high temperature corrosion, no easy-to-peel oxide scale below 1082℃, commonly used in combustion chambers

Ferritic stainless steel. Contains 12% to 30% chromium. Its corrosion resistance, toughness and weldability increase with the increase of chromium content, and its chloride stress corrosion resistance is better than other types of stainless steel.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

China Stainless Steel Pipe Chemical Compositions

|

Chemical Composition %

|

||||||||

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

|

201

|

≤0 .15

|

≤0 .75

|

5. 5-7. 5

|

≤0.06

|

≤ 0.03

|

3.5 -5.5

|

16 .0 -18.0

|

-

|

|

202

|

≤0 .15

|

≤l.0

|

7.5-10.0

|

≤0.06

|

≤ 0.03

|

4.0-6.0

|

17.0-19.0

|

-

|

|

301

|

≤0 .15

|

≤l.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

6.0-8.0

|

16.0-18.0

|

-

|

|

302

|

≤0 .15

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

8.0-10.0

|

17.0-19.0

|

-

|

|

304

|

≤0 .0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

8.0-10.5

|

18.0-20.0

|

-

|

|

304L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0-13.0

|

18.0-20.0

|

-

|

|

309S

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0-15.0

|

22.0-24.0

|

-

|

|

310S

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.035

|

≤ 0.03

|

19.0-22.0

|

24.0-26.0

|

|

|

316

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

10.0-14.0

|

16.0-18.0

|

2.0-3.0

|

|

316L

|

≤0 .03

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0 - 15.0

|

16 .0 -1 8.0

|

2.0 -3.0

|

|

321

|

≤ 0 .08

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0 - 13 .0

|

17.0 -1 9.0

|

-

|

|

630

|

≤ 0 .07

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

3.0-5.0

|

15.5-17.5

|

-

|

|

631

|

≤0.09

|

≤1.0

|

≤1.0

|

≤0.030

|

≤0.035

|

6.50-7.75

|

16.0-18.0

|

-

|

|

904L

|

≤ 2 .0

|

≤0.045

|

≤1.0

|

≤0.035

|

-

|

23.0·28.0

|

19.0-23.0

|

4.0-5.0

|

|

2205

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.030

|

≤0.02

|

4.5-6.5

|

22.0-23.0

|

3.0-3.5

|

|

2507

|

≤0.03

|

≤0.8

|

≤1.2

|

≤0.035

|

≤0.02

|

6.0-8.0

|

24.0-26.0

|

3.0-5.0

|

|

2520

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.045

|

≤ 0.03

|

0.19 -0. 22

|

0. 24 -0 . 26

|

-

|

|

410

|

≤0.15

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

-

|

11.5-13.5

|

-

|

|

430

|

≤0.1 2

|

≤0.75

|

≤1.0

|

≤ 0.040

|

≤ 0.03

|

≤0.60

|

16.0 -18.0

|

|

Industrial development changes rapidly, and stainless steel pipes also follow industrial development to meet the development needs of various industries. The following are the wide applications of stainless steel round pipes in various industries:

Water supply and drainage pipes, irrigation systems

Water supply and drainage pipeline engineering is for the transportation and distribution industry. Drinking water and collection. Transportation and discharge of industrial wastewater. Domestic sewage and rainwater pipe (channel) system engineering.

Engineering investment accounts for the majority of total engineering investment. Sprinkler irrigation systems are an important part of agricultural water use. The physical and chemical properties of stainless steel water pipes meet the requirements of modern agricultural water treatment.

These connection methods have different application scopes according to their different principles, but most of them are easy to install, strong and reliable. The sealing ring or gasket material used for the connection is mostly made of silicone rubber, nitrile rubber and EPDM rubber that meet national standards, which relieves users from worries.

1. Plastic sheet packaging

During transportation of stainless steel pipes, plastic sheets are often used to package the pipes. This packaging method is beneficial to protect the surface of the stainless steel pipe from wear, scratches and contamination, and also plays a role in moisture-proof, dust-proof and anti-corrosion.

2. Tape packaging

Tape packaging is an affordable, simple and easy way to package stainless steel pipes, usually using clear or white tape. The use of tape packaging can not only protect the surface of the pipeline, but also strengthen the strength of the pipeline and reduce the possibility of displacement or distortion of the pipeline during transportation.

3. Wooden pallet packaging

In the transportation and storage of large stainless steel pipes, wooden pallet packaging is a very practical way. The stainless steel pipes are fixed on the pallet with steel strips, which can provide very good protection and prevent the pipes from being collided, bent, deformed, etc. during transportation.

4. Carton packaging

For some smaller stainless steel pipes, carton packaging is a more common way. The advantage of carton packaging is that it is light and easy to transport. In addition to protecting the surface of the pipe, it can also be convenient for storage and management.

5. Container packaging

For large-scale stainless steel pipe exports, container packaging is a very common way. Container packaging can ensure that pipelines are transported safely and without accidents at sea, and avoid deviations, collisions, etc. during transportation.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Our Customer

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.