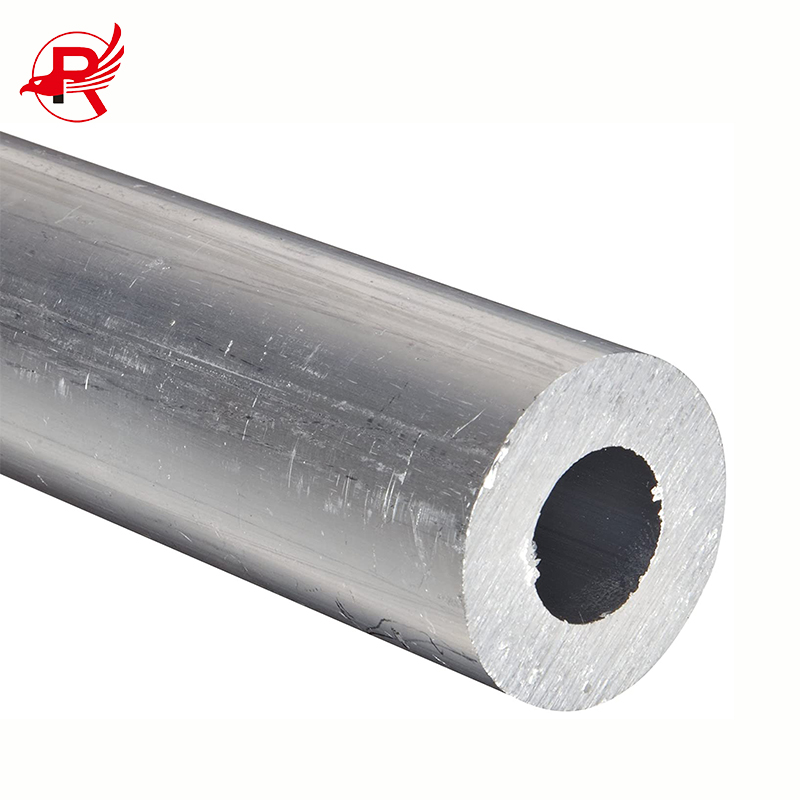

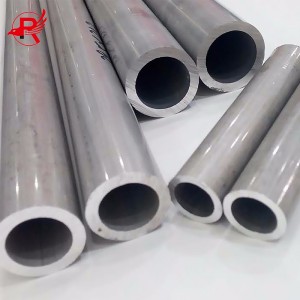

China Supplier Aluminum Round Tubing 6063 Aluminum Pipe

|

Products Name

|

Aluminum Round Pipe | |||

|

Material Grade

|

1000 series: 1050,1060,1070,1080,1100,1435, etc

2000 series: 2011,2014,2017,2024, etc 3000 series: 3002,3003,3104,3204,3030, etc 5000 series: 5005,5025,5040,5056,5083, etc 6000 series: 6101,6003,6061,6063,6020,6201,6262,6082, etc 7000 series: 7003,7005,7050,7075, etc |

|||

|

Size

|

Outer Diameter:3-250mm

|

|||

|

Wall Thickness: 0.3-50mm

|

||||

|

Length: 10mm -6000mm

|

||||

|

Standards

|

ASTM, ASME,EN, JIS, DIN,GB/T etc

|

|||

|

Surface treatment

|

Mill finished,anodized,powder coating,Sand blast,etc

|

|||

|

Surface colors

|

Nature, silver, bronze, champagne, black, gloden, etc

As customized |

|||

|

Status

|

T4 T5 T6 or other special status

|

|||

|

Usage

|

Aluminum profile for windows/ doors/ decoration/ construction/ curtain wall

|

|||

|

Quality

|

China Nation Standard GB/T

|

|||

|

Packing

|

Protective film +plastic film or EPE +kraft paper

|

|||

|

Certificate

|

ISO 9001:2008

|

|||

|

Series

|

Represent

|

Features

|

|

1000 series

|

1050,1060,1100

|

Among all the series, the 1000 series belongs to the series with the most aluminum content.

|

|

2000 series

|

2A16 (LY16),2A02 (LY6)

|

2000 series aluminum tubes are characterized by high hardness, among which the copper content is the highest, about 3-5%. The main uses of 2024 aluminum tubes: aircraft structures, rivets, truck hubs,propeller assemblies and various other structural parts.

|

|

3000 series

|

3003,3A21

|

3000 series aluminum tubes are mainly composed of manganese. The content is between 1.0-1.5, which is a series with better anti-rust function.

|

|

4000 series

|

4A01

|

4000 series aluminum tubes belong to the series with higher silicon content. It belongs to building materials, mechanical parts, forging materials,welding materials.

|

|

5000 series

|

5052,5005,5083,5A05

|

The main features are low density, high tensile strength and high elongation.

|

|

6000 series

|

6061.6063

|

It mainly contains magnesium and silicon and is suitable for applications requiring high corrosion resistance and oxidation

resistance Good workability, easy to coat, and good workability. |

|

7000 series

|

7075

|

lt is an aluminum-magnesium-zinc-copper alloy, a heat-treatable alloy, a super-hard aluminum alloy with good wear resistance.

|

Aluminum round pipes are widely used in many fields due to their lightweight, corrosion-resistant and easy-to-process properties. The following are common uses of aluminum round tubes:

- Architecture and construction engineering: used to make building structures, interior decorations, door and window frames, etc.

- Electrical engineering: used to make wire tubes, cable protective sleeves, power transmission lines, etc.

- Transportation: used to make parts for cars, bicycles, motorcycles and other vehicles, such as body structures, door frames, etc.

- Refrigeration and air conditioning: used to make air conditioning pipes, refrigeration equipment, etc.

- Chemical industry: used in the production of chemical equipment, pipes, containers, etc. due to its corrosion resistance.

- Medical equipment: used to make medical equipment, wheelchairs, walkers, etc.

- Furniture manufacturing: Used to make brackets, frames and other components of furniture.

- Aerospace: Used to make aerospace components such as airplanes and rockets due to its lightweight characteristics.

In general, aluminum round pipes are widely used in industry, construction, transportation, electrical and other fields. Its lightweight, corrosion-resistant, and easy-to-process characteristics make it one of the indispensable materials in many industries.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

The production of Aluminum Tube is based on pure aluminum and aluminum alloy strips with good weldability as blanks, which are pretreated first, and the strip blanks are cut into the required width of the welded pipe. Finished wall-welded tubes, or further processing as drawn tube blanks.- Aluminum ingot melting: First, the aluminum ingot is heated to the melting temperature, usually between 700°C and 900°C. Once melted, the liquid aluminum can be used for subsequent processing.

Drawing: Molten aluminum is drawn into the desired tubular shape. This is usually accomplished by passing molten aluminum through a die or die combination to obtain the required tube diameter and wall thickness.

Curing: Once formed into the desired tubular shape, the aluminum tube is cooled to solidify its structure.

Surface treatment: Aluminum pipe may require surface treatment, such as anodizing, to enhance its corrosion resistance and appearance.

Cutting and shaping: Aluminum pipes may need to be cut and shaped according to customer requirements to obtain the desired length and shape.

Inspection and packaging: Finally, the aluminum tube will undergo quality inspection to ensure that it meets relevant standards and specifications, and then packaged for easy transportation and storage.

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.