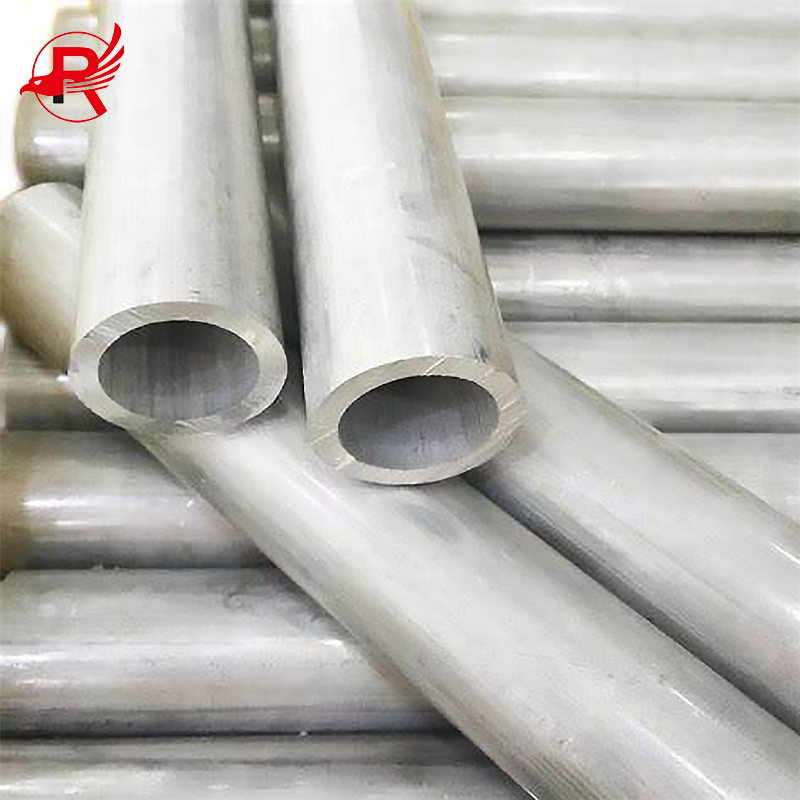

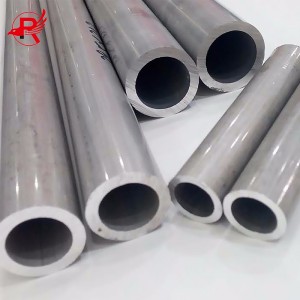

China Factory Price 7075 Aluminum Alloy Tube

| Product Name | Aluminum Tube |

| Grade | 1000, 3000, 5000, 6000, 7000 series |

| Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

| Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 6060 6061 6063, 7075,etc |

| Surface treatment | mill finish, sandblasting, anodizing, electrophoresis, polishing, power coating, PVDF coating, wood transfer, etc. |

| Standard | ASTM,GB,AISI,DIN,JIS,etc |

| Application | 1.LED light industry2.Solar industry3.Sanitary industry4.Auto party industry5.Heat sink industry and etc |

| Wall Thickness | 0.8~3 mm or customizable |

| Outer Diameter | 10 to 100 mm or customizable |

| MOQ | 3 tons per size |

| Delivery port | Tianjin , China (any port in China ) |

| Remark | Specific requirement of alloy grade,temper or specification can be discussed at your request |

Aluminum pipes are lightweight, corrosion-resistant, and easy to process, so they have a wide range of application scenarios in many fields, including but not limited to:

- Architecture and construction engineering: used to make building structures, door and window frames, roof structures, interior decoration, etc.

- Electrical engineering: used to make wire tubes, cable protective sleeves, power transmission lines, etc.

- Transportation: used to make parts for vehicles such as cars, trains, and airplanes, such as body structures, door frames, etc.

- Chemical industry: used in the production of chemical equipment, pipes, containers, etc. due to its corrosion resistance.

- Furniture manufacturing: used to make brackets, frames and other components of furniture.

- Medical equipment: used to make medical equipment, wheelchairs, walkers, etc.

- Aerospace: used to make aerospace components such as airplanes and rockets due to its lightweight characteristics.

- Packaging industry: used to make packaging containers, bottle caps, etc.

In general, aluminum pipes are widely used in industry, construction, transportation, electrical and other fields. Its light weight, corrosion resistance, and easy processing characteristics make it one of the indispensable materials in many industries.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

The production of Aluminum Round Tube is based on pure aluminum and aluminum alloy strips with good weldability as blanks, which are pretreated first, and the strip blanks are cut into the required width of the welded pipe. Finished wall-welded tubes, or further processing as drawn tube blanks.

The production process of aluminum tubes usually includes the following steps:

- Aluminum ingot melting: First, the aluminum ingot is heated to the melting temperature, usually between 700°C and 900°C. Once melted, the liquid aluminum can be used for subsequent processing.

- Drawing: The molten aluminum liquid is drawn into the required tubular shape. This is usually accomplished by passing molten aluminum through a die or die combination to obtain the required tube diameter and wall thickness.

- Curing: Once formed into the desired tubular shape, the aluminum tube is cooled to solidify its structure.

- Surface treatment: Aluminum pipe may require surface treatment, such as anodizing, to enhance its corrosion resistance and appearance.

- Cutting and shaping: Aluminum pipes may need to be cut and shaped according to customer requirements to obtain the required length and shape.

- Inspection and packaging: Finally, the aluminum tube will undergo quality inspection to ensure that it meets relevant standards and specifications, and then packaged for easy transportation and storage.

These steps may vary depending on the production process and the intended use of the final product, but generally constitute the basic process for aluminum tube production.

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China. Besides, we cooperate with many state-owned enterprises, such as BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP,etc.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.