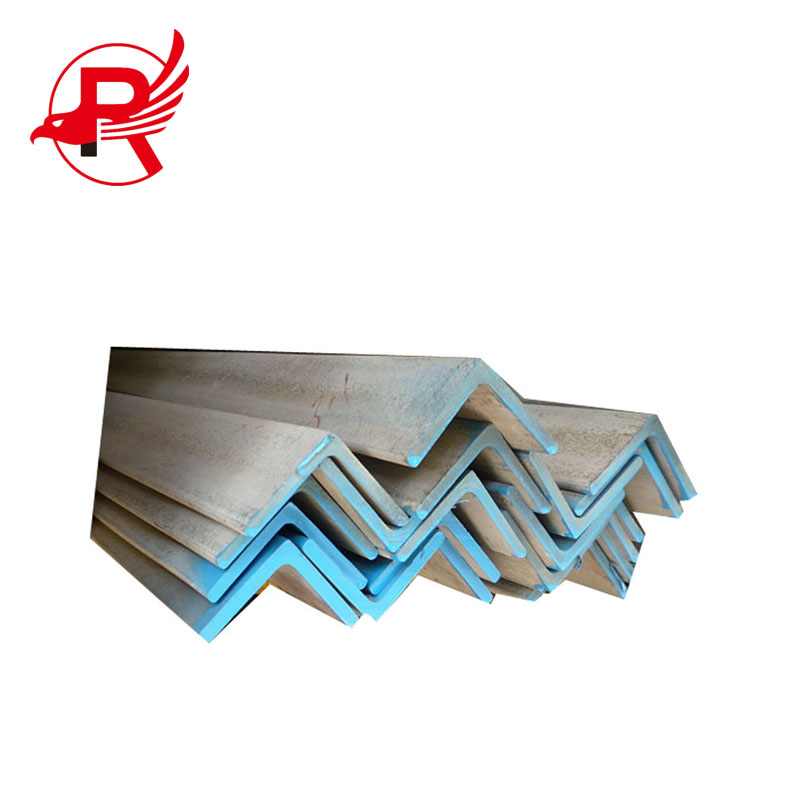

China Factory Hot Rolled Mild Carbon Galvanized ST37 Steel Angle Bar for Construction

Angle Steel Bar is divided into hot-dip galvanized angle steel and cold-dip galvanized angle steel. Hot-dip galvanized angle steel is also called hot-dip galvanized angle steel or hot-dip galvanized angle steel. The cold-dip galvanized coating mainly ensures the full contact between the zinc powder and the steel through the electrochemical principle, and generates an electrode potential difference for anti-corrosion.

Hot-dip galvanized angle steel is also called hot-dip galvanized angle steel or hot-dip galvanized angle steel. It is to immerse the angle steel after derusting in the molten zinc at about 500 ℃, so that the surface of the angle steel is attached with a zinc layer, so as to achieve the purpose of anticorrosion, and it is suitable for various strong corrosive environments such as strong acid and alkali mist.

Process: hot-dip galvanized angle steel process: angle steel pickling → water washing → immersion in plating solvent → drying and preheating → rack plating → cooling → passivation → cleaning → grinding → hot-dip galvanizing completed.

The cold galvanizing process is used to protect metals from corrosion. For this purpose, a coating of zinc filler is used. It is applied to the surface to be protected by any coating method. After drying, a zinc filler coating is formed. In the dry coating Has a high content of zinc (up to 95%). Suitable for repair work (i.e. during repair work, only where the protected steel surface has been damaged, it can be reapplied as soon as the surface has been repaired). The cold galvanizing process is used for the anticorrosion of various steel products and structures.

Carbon Steel Angle Bar are commonly used in the construction industry as it is a durable and cost-effective material. Following are some of the main properties of galvanized steel angles:

1. Durability: Galvanized angle steel is durable. Zinc coatings help protect steel from rust and corrosion, which can lead to structural damage over time. This makes galvanized steel angle an excellent choice for outdoor construction projects as it can withstand harsh weather conditions.

2. Cost-effective: Compared with many other building materials, the price of galvanized angle steel is relatively affordable. It can be purchased in large quantities at a relatively low cost, making it an attractive option for budget-conscious builders and contractors.

3. Fire resistance: galvanized steel angle bar has excellent fire resistance grade. It does not catch fire or burn easily, making it a safe choice for use on buildings and structures.

4. Versatility: Galvanized angle steel can be used in many kinds of construction projects. It is commonly used in building frames, supports and beams, as well as machinery and equipment.

5. Beautiful: The galvanized layer of galvanized angle steel makes the appearance bright and beautiful. This makes it a popular choice for architectural and design projects where aesthetics are important.

6. Low maintenance: Galvanized angle steel requires very little maintenance. It is resistant to rust and corrosion, so it does not need to be painted or coated with additional protective materials.

7. Easy to machine: Galvanized steel angles are easy to machine and are a popular choice for DIY projects. It can be cut, drilled and welded to suit a variety of applications.

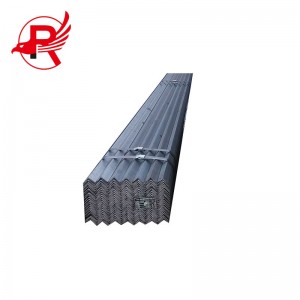

Galvanized angle steel is widely used in power towers, communication towers, curtain wall materials, shelf construction, railways, road protection, street light poles, marine components, building steel structure components, substation ancillary facilities, light industry,etc.

| Product name | Angle Bar |

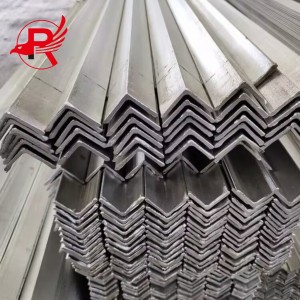

| Grade | Q235B, SS400, ST37, SS41, A36 etc |

| Type | GB Standard, European Standard |

| Length | Standard 6m and 12m or as customer requirement |

| Technique | Hot Rolled |

| Application | Wide used in curtain wall materials, shelf construction, railways etc. |

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact

us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 5-20 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5. What kinds of payment methods do you accept?

30% in advance by T/T, 70% will be before shippment basic on FOB; 30% in advance by T/T, 70% against the copy of BL basic on CIF.