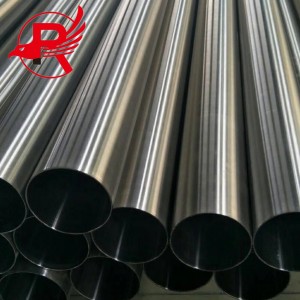

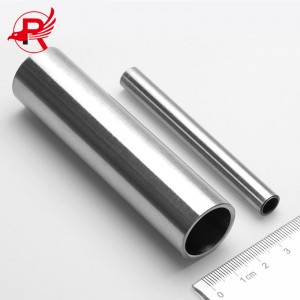

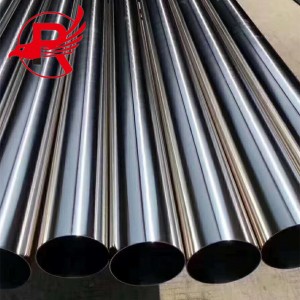

ASTM API 304 A106 A36 Stainless Steel Seamless Steel Pipe

|

tem

|

304 Stainless Steel Pipe |

|

Standard

|

JIS, AiSi, ASTM, GB, DIN, EN

|

|

Place of Origin

|

China

|

|

Brand Name

|

ROYAL

|

|

Type

|

Seamless / Weld

|

|

Steel Grade

|

200/300/400 Series, 904L S32205 (2205),S32750(2507)

|

|

Application

|

Chemical industry, mechanical equipment

|

|

Processing Service

|

Bending, Welding, Decoiling, Punching, Cutting, Moulding

|

|

Technique

|

Hot rolled/cold rolled

|

|

Payment terms

|

L/C T/T (30%DEPOSIT)

|

|

Price Term

|

CIF CFR FOB EX-WORK

|

Due to its strong corrosion resistance, stainless steel pipes have relatively low maintenance costs and long service life.Stainless steel pipes have high strength and hardness. This allows it to withstand high pressure and heavy loads. Therefore, stainless steel pipes are widely used in building structures, mechanical components and other fields. At the same time, its plasticity and toughness also make it an ideal material for making pipes.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Stainless Steel Pipe Chemical Compositions

|

Chemical Composition %

|

||||||||

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

|

201

|

≤0 .15

|

≤0 .75

|

5. 5-7. 5

|

≤0.06

|

≤ 0.03

|

3.5 -5.5

|

16 .0 -18.0

|

-

|

|

202

|

≤0 .15

|

≤l.0

|

7.5-10.0

|

≤0.06

|

≤ 0.03

|

4.0-6.0

|

17.0-19.0

|

-

|

|

301

|

≤0 .15

|

≤l.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

6.0-8.0

|

16.0-18.0

|

-

|

|

302

|

≤0 .15

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

8.0-10.0

|

17.0-19.0

|

-

|

|

304

|

≤0 .0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

8.0-10.5

|

18.0-20.0

|

-

|

|

304L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0-13.0

|

18.0-20.0

|

-

|

|

309S

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0-15.0

|

22.0-24.0

|

-

|

|

310S

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.035

|

≤ 0.03

|

19.0-22.0

|

24.0-26.0

|

|

|

316

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

10.0-14.0

|

16.0-18.0

|

2.0-3.0

|

|

316L

|

≤0 .03

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0 - 15.0

|

16 .0 -1 8.0

|

2.0 -3.0

|

|

321

|

≤ 0 .08

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0 - 13 .0

|

17.0 -1 9.0

|

-

|

|

630

|

≤ 0 .07

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

3.0-5.0

|

15.5-17.5

|

-

|

|

631

|

≤0.09

|

≤1.0

|

≤1.0

|

≤0.030

|

≤0.035

|

6.50-7.75

|

16.0-18.0

|

-

|

|

904L

|

≤ 2 .0

|

≤0.045

|

≤1.0

|

≤0.035

|

-

|

23.0·28.0

|

19.0-23.0

|

4.0-5.0

|

|

2205

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.030

|

≤0.02

|

4.5-6.5

|

22.0-23.0

|

3.0-3.5

|

|

2507

|

≤0.03

|

≤0.8

|

≤1.2

|

≤0.035

|

≤0.02

|

6.0-8.0

|

24.0-26.0

|

3.0-5.0

|

|

2520

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.045

|

≤ 0.03

|

0.19 -0. 22

|

0. 24 -0 . 26

|

-

|

|

410

|

≤0.15

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

-

|

11.5-13.5

|

-

|

|

430

|

≤0.1 2

|

≤0.75

|

≤1.0

|

≤ 0.040

|

≤ 0.03

|

≤0.60

|

16.0 -18.0

|

|

Stainless steel pipes look beautiful and are easy to clean. This makes it widely used in some occasions with high appearance requirements, such as kitchen utensils. In general, stainless steel pipes have become an indispensable and important material in many industries due to their good corrosion resistance, high strength and beautiful appearance. In the future, with the development of science and technology, we expect that stainless steel pipes will have more innovative applications and make greater contributions to the development of society.

Performance characteristics and uses of stainless steel pipes of different materials. 304 stainless steel welded pipe: has good corrosion resistance, heat resistance, low temperature strength and mechanical properties, good hot workability such as stamping and bending, and no heat treatment hardening phenomenon. Usage: tableware, cabinets, boilers, auto parts, medical equipment, building materials, food industry.

There are various connection methods for stainless steel pipes. Common pipe fitting types include compression type, compression type, union type, push type, push thread type, socket welding type, union flange connection, welding type and welding and traditional connection. Combined derived series connection methods. These connection methods have different application scopes according to their different principles, but most of them are easy to install, strong and reliable. The sealing ring or gasket material used for the connection is mostly made of silicone rubber, nitrile rubber and EPDM rubber that meet national standards, which relieves users from worries.

1. Plastic sheet packaging

During transportation of ss stainless steel tube, plastic sheets are often used to package the pipes. This packaging method is beneficial to protect the surface of the stainless steel pipe from wear, scratches and contamination, and also plays a role in moisture-proof, dust-proof and anti-corrosion.

2. Tape packaging

Tape packaging is an affordable, simple and easy way to package stainless steel pipes, usually using clear or white tape. The use of tape packaging can not only protect the surface of the pipeline, but also strengthen the strength of the pipeline and reduce the possibility of displacement or distortion of the pipeline during transportation.

3. Wooden pallet packaging

In the transportation and storage of large stainless steel pipes, wooden pallet packaging is a very practical way. The stainless steel pipes are fixed on the pallet with steel strips, which can provide very good protection and prevent the pipes from being collided, bent, deformed, etc. during transportation.

4. Carton packaging

For some smaller stainless steel pipes, carton packaging is a more common way. The advantage of carton packaging is that it is light and easy to transport. In addition to protecting the surface of the pipe, it can also be convenient for storage and management.

5. Container packaging

For large-scale stainless steel pipe exports, container packaging is a very common way. Container packaging can ensure that pipelines are transported safely and without accidents at sea, and avoid deviations, collisions, etc. during transportation.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Our Customer

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.