ASTM A36-14 A36 Low Carbon Mild HRC Steel Coil

|

Product Name |

ASTM A36-14 A36 Low Carbon Mild HRC Hot Rolled Steel Coil |

|

Material |

Q195/Q235/Q345/A36/S235JR/S355JR |

|

Thickness |

1.5mm~24mm |

|

Size |

3x1219mm 3.5x1500mm 4x1600mm 4.5x2438mm customized |

|

Standard |

ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS |

| 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |

|

Grade |

A53-A369, Q195-Q345, ST35-ST52 |

| Grade A, Grade B, Grade C | |

|

Technique |

Hot rolled |

|

Packing |

Bundle, or with all kinds of colors PVC or as your requirements |

|

Pipe Ends |

Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. |

|

MOQ |

1 Tons, more quantity price will be lower |

|

Surface Treatment |

1. Mill finished /Galvanized /stainless steel |

| 2. PVC,Black and color painting | |

| 3. Transparent oil,anti-rust oil | |

| 4. According to clients requirement | |

|

Product Application |

|

|

|

|

|

|

|

|

Origin |

Tianjin China |

|

Certificates |

ISO9001-2008,SGS.BV,TUV |

|

Delivery Time |

Usually within 10-15 days after receipt of advance payment |

The thickness is produced inaccordance with the contract.Our company process the thicknesstolerance is within ±0.01mm.Laser cutting nozzle, the nozzle issmooth and neat.Can be custom cut to any width from20mm to 1500mm.50.000 mwarehouse.produces morethan 5,000 tons Carbon Steel Coil ofgoods per day.so we can providethem with fastestshipping time andcompetitive price.

| Thickness(mm) | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | customized |

| Width(mm) | 800 | 900 | 950 | 1000 | 1219 | 1000 | customized |

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Carbon Steel Coil Manufacturers of straight seam welded pipe is simple, the production efficiency is high, the cost is low, and the development is rapid. The strength of the spiral welded pipe is generally higher than that of the straight seam welded pipe, and the welded pipe with a larger diameter can be produced with a narrower billet, and welded pipes with different diameters can be produced with the same width billet. But compared with the straight seam pipe of the same length, the weld length is increased by 30~100%, and the production speed is lower.

Application Range

The products are widely used in water supply engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, and urban construction. It is one of the twenty key Cold Rolled Carbon Steel Coil developed by our country.

Used for liquid transportation: water supply and drainage. For gas transportation: gas, steam, liquefied petroleum gas.

For structural purposes: as piling pipes, as bridges; pipes for wharves, roads, building structures, etc.

Raw material preparation

Iron ore, coke and limestone are used as the main raw materials. Liquid pig iron is obtained by smelting in a blast furnace, and then impurities are removed by refining in a converter or electric furnace. After adjusting the composition, molten steel is formed.

Continuous casting

The molten steel is continuously cast into billets of a certain size (such as slabs and billets), and cut into the required length after cooling.

Heating process

The billet is sent to the heating furnace and heated to a high temperature of about 1100-1300℃ to soften it for subsequent rolling.

Rough rolling and finishing rolling

Rough rolling: The billet is initially thinned through multiple rolling passes to form a thicker intermediate strip.

Finishing rolling: Further thinning to the target thickness (usually 0.8-25mm), while controlling the plate shape and surface quality.

Cooling treatment

The laminar cooling system is used to quickly cool to room temperature, and the internal structure of the steel is optimized by controlling the cooling rate (such as grain refinement).

Coiling

The cooled steel strip is coiled into a steel coil to form a hot-rolled finished product.

Quality inspection and warehousing

Inspect dimensions, mechanical properties, surface defects, etc., and pack and warehouse after passing the inspection or send for subsequent processing (such as cold rolling, coating and plating).

Hot rolled steel coils have many benefits, including:

It has a high strength-to-weight ratio, making it ideal for the construction and shipbuilding industries.

Highly resistant to corrosion and abrasion, ideal for use in pressure vessels and piping systems.

It has excellent weldability and formability, making it suitable for a variety of manufacturing processes.

Usually bare package

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

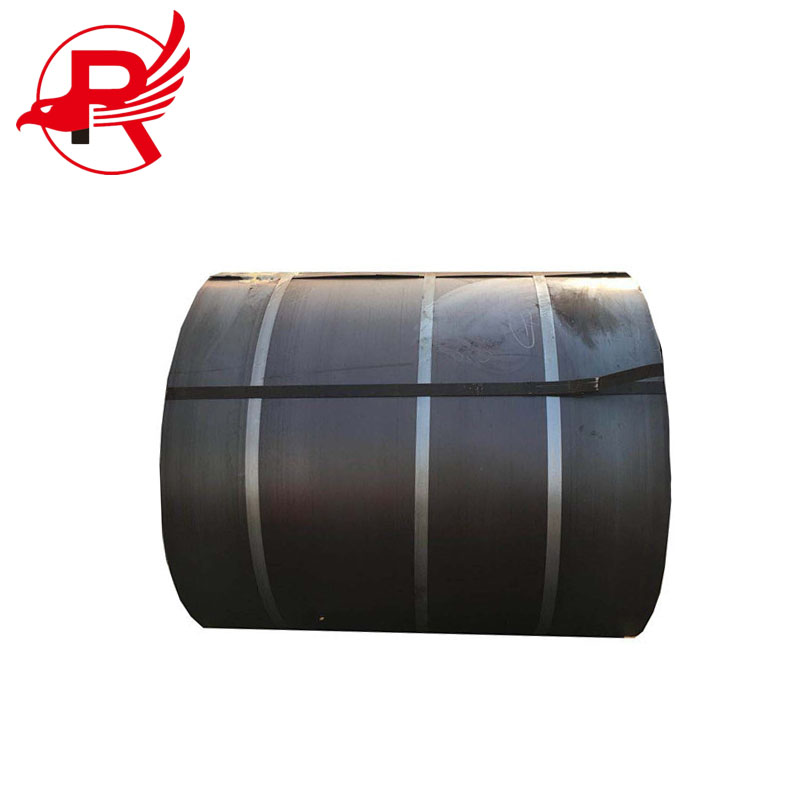

How to pack steel coils

1. Cardboard tube packaging: Place the Carbon Steel Coil in a cylinder made of cardboard, cover it at both ends, and seal it with tape;

2. Plastic strapping and packaging: Use plastic straps to bundle the steel coils into a bundle, cover them at both ends, and wrap them with plastic straps to fix them;

3. Cardboard gusset packaging: Fasten the steel coil with cardboard cleats and stamp both ends;

4. Iron buckle packaging: Use strip iron buckles to bundle the steel coils into a bundle and stamp both ends

In short, the packaging method of steel coils needs to take into account the needs of transportation, storage and use. The steel coil packaging materials must be strong, durable and tightly tied to ensure that the packaged steel coils will not be damaged during transportation. At the same time, safety needs to be paid attention to during the packaging process to avoid injuries to people, machinery, etc. due to packaging.

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Daqiuzhuang Village, Tianjin City, China. Besides, we cooperate with many state-owned enterprises, such as BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP,etc.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.