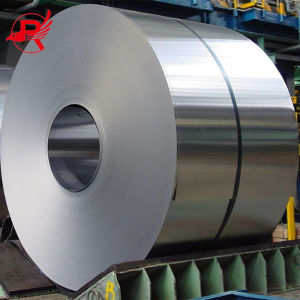

ASTM 301 302 303 Hot / Cold Rolled Stainless Steel Coil For Construction

| Product Name | 301 302 303 stainless steel coil |

| Grades | 201/EN 1.4372/SUS201 |

| Hardness | 190-250HV |

| Thickness | 0.02mm-6.0mm |

| Width | 1.0mm-1500mm |

| Edge | Slit/Mill |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror,etc |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 7-15 working days |

| MOQ | 200Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of 301 302 303 stainless steel coil is available |

201 is a low carbon stainless steel that offers excellent weldability, good corrosion resistance and high strength. It is an ideal material for a wide variety of applications including food processing equipment and chemical processing equipment.

The following is a list of some of the more common applications for 301 302 303 stainless steel coils:

1. Food Processing Equipment & Chemical Processing Equipment

2. Oil & Gas Industries

3. Marine Applications

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Stainless Steel Coil Chemical Compositions

|

Chemical Composition %

|

||||||||

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

|

201

|

≤0 .15

|

≤0 .75

|

5. 5-7. 5

|

≤0.06

|

≤ 0.03

|

3.5 -5.5

|

16 .0 -18.0

|

-

|

|

202

|

≤0 .15

|

≤l.0

|

7.5-10.0

|

≤0.06

|

≤ 0.03

|

4.0-6.0

|

17.0-19.0

|

-

|

|

301

|

≤0 .15

|

≤l.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

6.0-8.0

|

16.0-18.0

|

-

|

|

302

|

≤0 .15

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

8.0-10.0

|

17.0-19.0

|

-

|

|

304

|

≤0 .0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

8.0-10.5

|

18.0-20.0

|

-

|

|

304L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0-13.0

|

18.0-20.0

|

-

|

|

309S

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0-15.0

|

22.0-24.0

|

-

|

|

310S

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.035

|

≤ 0.03

|

19.0-22.0

|

24.0-26.0

|

|

|

316

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

10.0-14.0

|

16.0-18.0

|

2.0-3.0

|

|

316L

|

≤0 .03

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0 - 15.0

|

16 .0 -1 8.0

|

2.0 -3.0

|

|

321

|

≤ 0 .08

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0 - 13 .0

|

17.0 -1 9.0

|

-

|

|

630

|

≤ 0 .07

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

3.0-5.0

|

15.5-17.5

|

-

|

|

631

|

≤0.09

|

≤1.0

|

≤1.0

|

≤0.030

|

≤0.035

|

6.50-7.75

|

16.0-18.0

|

-

|

|

904L

|

≤ 2 .0

|

≤0.045

|

≤1.0

|

≤0.035

|

-

|

23.0·28.0

|

19.0-23.0

|

4.0-5.0

|

|

2205

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.030

|

≤0.02

|

4.5-6.5

|

22.0-23.0

|

3.0-3.5

|

|

2507

|

≤0.03

|

≤0.8

|

≤1.2

|

≤0.035

|

≤0.02

|

6.0-8.0

|

24.0-26.0

|

3.0-5.0

|

|

2520

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.045

|

≤ 0.03

|

0.19 -0. 22

|

0. 24 -0 . 26

|

-

|

|

410

|

≤0.15

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

-

|

11.5-13.5

|

-

|

|

430

|

≤0.1 2

|

≤0.75

|

≤1.0

|

≤ 0.040

|

≤ 0.03

|

≤0.60

|

16.0 -18.0

|

|

Through different processing methods of cold rolling and surface reprocessing after rolling, the surface finish of 201 stainless steel coils can have different types.

A production process is a series of steps involved in transforming raw materials into finished products. It is a key part of manufacturing as it allows companies to produce goods that meet customer needs in a cost-effective manner.

A production process usually involves a series of stages, each involving different tasks, machines and people. These stages may include:

1. Design and planning: This stage includes determining product specifications, selecting raw materials, and detailing the production process.

2. Raw material acquisition: This stage involves the procurement, transportation and storage of raw materials required for production.

3. Pre-production preparation: This phase involves preparing raw materials for the production process, such as cleaning, cutting or shaping.

4. Manufacturing: This is the main stage of the production process where raw materials are transformed into finished products. This phase involves various tasks such as assembling, welding, cutting or shaping materials.

5. Quality Control: This phase involves checking the finished products to ensure they meet the necessary quality standards. Any deficiencies or problems are identified and corrected at this stage.

6. Packing and Shipping: This stage involves packing the finished product and shipping it to its final destination.

the standard sea packaging of stainless steel coil

Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case;

Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

Other special packaging will be designed as customer’s request;

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.