-

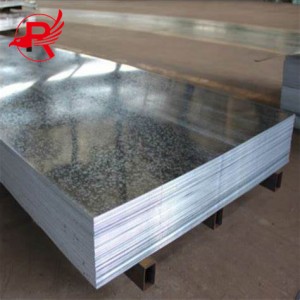

Hot-Selling High Quality Galvanized Steel Roof Galvanized Metal Sheet

Stainless steel sheet is a material with excellent corrosion resistance, strength and aesthetics, which is widely used in many industries such as construction, food processing, medical treatment and automotive. Its surface is smooth and easy to clean, which is very suitable for occasions with high requirements for hygiene and aesthetics. At the same time, the recyclability of stainless steel makes it an important material to support sustainable development. With the advancement of technology, the application of stainless steel plates will be more diversified and continue to play an important role in modern industry and life.

-

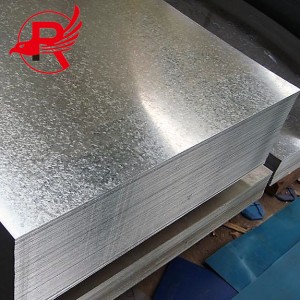

Hot Sales Top Quality Dx52d Z140 Galvanized Steel Sheet for Building Iron Roof Sheet

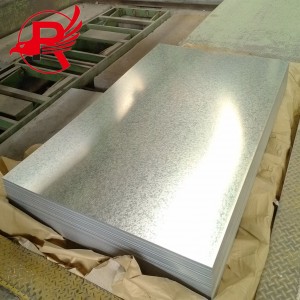

Galvanized sheet is a kind of metal material that is coated with zinc on the surface of steel plate, mainly used to prevent steel corrosion and increase its durability. Galvanized sheet is usually a hot-dip galvanizing process, that is, the steel plate is immersed in a molten zinc solution to form a uniform zinc layer on its surface. This treatment can effectively prevent the steel from being eroded by air, water and chemicals, and extend its service life.

Galvanized sheet is widely used in construction, furniture, automobile manufacturing, power equipment and other fields. In the construction industry, galvanized sheets are often used to make components such as roofs, walls, pipes and doors and Windows to improve their corrosion resistance and aesthetics. In the automotive industry, galvanized sheets are used to make body shells and components to increase their weather resistance and durability.

In general, galvanized sheet has good corrosion resistance and mechanical properties, is an important metal material, for protecting steel from corrosion and extending its service life plays an important role.

-

Factory Supply Z275 Dx51d Cold Rolled Dipped Gi Galvanized Steel Sheets

Galvanized sheet refers to a steel sheet coated with a layer of zinc on the surface. Galvanizing is an economical and effective rust prevention method that is often used, and about half of the world’s zinc production is used in this process.

-

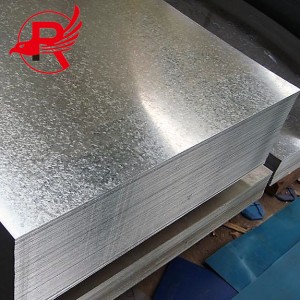

High Quality Dx51d Galvanized Steel Plate Price

The zinc layer of Galvanized sheet refers to a layer of zinc coating formed on the surface of ordinary steel sheets. The formation of this layer of zinc coating is achieved through the hot-dip galvanizing process, which involves immersing the steel plate in molten zinc liquid so that the surface of the steel plate is evenly covered with a layer of zinc. This zinc layer is dense and uniform, and can effectively block the erosion of the steel plate by atmosphere, water and chemical substances, thus improving the corrosion resistance of the steel plate. The zinc layer also has good wear resistance and can protect the surface of the steel plate from friction and wear. In addition, the zinc layer also provides good weather resistance and can maintain stable performance under harsh climate conditions. In addition, the formation of the zinc layer also makes the galvanized sheet have good processing performance, and can be processed by bending, stamping, welding, etc., and is suitable for the manufacturing of various complex shapes. In general, the zinc layer of galvanized sheets is the key to its excellent corrosion resistance, wear resistance, weather resistance and other characteristics, making galvanized sheets widely used in construction, machinery, electricity, communications and other fields.

-

High Quality Building Materials 0.12-4.0mm SPCC Cold Rolled Galvanized Steel Sheet

Galvanized sheet is a product that is coated with a layer of zinc on the surface of ordinary steel sheets. The purpose of galvanizing is to improve the corrosion resistance of steel plates, because zinc has good anti-corrosion properties. Galvanized sheets usually use a hot-dip galvanizing process, which involves immersing the steel sheet in molten zinc liquid to form a uniform and dense zinc layer. This treatment gives galvanized sheets excellent corrosion resistance, wear resistance and weather resistance. The production process of galvanized sheets includes multiple steps such as raw material preparation, smelting zinc liquid, hot-dip galvanizing, and surface treatment. The characteristics of galvanized sheets include excellent corrosion resistance, wear resistance, good processing performance, smooth and beautiful surface, and good electrical conductivity. Galvanized sheets are widely used in construction, machinery, electricity, communications and other fields, and are often used in building structures, drainage systems, industrial equipment, agricultural machinery, transportation and other fields. Its corrosion resistance makes it one of the indispensable materials in various industries.

-

ASTM A653M-06a Galvanized Steel Sheet

Galvanized sheet is a product that is coated with a layer of zinc on the surface of ordinary steel sheets. The purpose of galvanizing is to improve the corrosion resistance of steel plates, because zinc has good anti-corrosion properties. Galvanized sheets usually use a hot-dip galvanizing process, which involves immersing the steel sheet in molten zinc liquid to form a uniform and dense zinc layer. This treatment gives galvanized sheets excellent corrosion resistance, wear resistance and weather resistance. The production process of galvanized sheets includes multiple steps such as raw material preparation, smelting zinc liquid, hot-dip galvanizing, and surface treatment. The characteristics of galvanized sheets include excellent corrosion resistance, wear resistance, good processing performance, smooth and beautiful surface, and good electrical conductivity. Galvanized sheets are widely used in construction, machinery, electricity, communications and other fields, and are often used in building structures, drainage systems, industrial equipment, agricultural machinery, transportation and other fields. Its corrosion resistance makes it one of the indispensable materials in various industries.

-

Astm A36 S335 3mm Thick Hot Dip Galvanized Steel Sheet

Galvanized sheet is a product that is coated with a layer of zinc on the surface of ordinary steel sheets to improve the corrosion resistance of the steel sheets. Galvanized sheets usually use a hot-dip galvanizing process, which involves immersing the steel sheet in molten zinc liquid to form a uniform and dense zinc layer. This treatment gives galvanized sheets excellent corrosion resistance, wear resistance and weather resistance.

Galvanized sheets are widely used in construction, furniture, automobile manufacturing, electricity, communications and other fields. In the construction field, galvanized sheets are often used to make roofs, walls, pipes, doors and windows, etc., because their corrosion resistance can effectively extend their service life. In furniture manufacturing, galvanized sheets can be used to make the metal frame and shell of furniture to improve the durability of the product. In automobile manufacturing, galvanized sheets can be used in the manufacture of automobile body panels to improve the durability of the automobile. In the fields of power and communications, galvanized sheets can be used to make cable sheaths, communication equipment casings, etc., because their corrosion resistance can ensure the safe operation of equipment.

In general, galvanized sheets have become one of the indispensable materials in various industrial fields due to their excellent corrosion resistance and wide range of applications.

-

ASTM A653 Metal 26 28 30 Gauge Galvanized Steel Sheet

Galvanized sheet is a galvanized steel sheet that has the advantages of anti-corrosion, good fire resistance, and high durability. It is widely used in construction, transportation, agriculture and other fields.

-

High Quality Good Price DX54D Sheet Galvanized Steel Corrugated Metal Roof Tiles Cold Rolled Roofing Sheet

When transporting and installing galvanized sheets, avoid scratches and collisions to prevent damage to the galvanized layer and affect the anti-corrosion performance of the galvanized sheets.

-

Good Quality Q235 Galvanized Steel Sheet

Galvanized sheet refers to a steel sheet coated with a layer of zinc on the surface. Galvanizing is an economical and effective anti-rust method that is often used. About half of the world’s zinc production is used in this process.

-

Factory Direct Supply G90 Z275 Galvanized Steel Sheet

Galvanized sheet and strip products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commercial industries. Among them, the construction industry is mainly used to make anti-corrosion industrial and civil building roof panels, roof grilles, etc.; the light industry industry is mainly used to make home appliance casings, civil chimneys, kitchen utensils, etc.; the automotive industry is mainly used to make corrosion-resistant parts for cars, etc. ; Agriculture, animal husbandry and fishery are mainly used for grain storage and transportation, freezing processing equipment for meat and aquatic products, etc.; commerce is mainly used for material storage and transportation, packaging equipment, etc.

-

Roof Steel Material Dx53D Zinc Coated Corrugated Galvanized Steel Roofing Sheet

Galvanized sheets combine the properties of steel and zinc and are strong and durable. They are used in household appliances such as refrigerators, microwave ovens, washing machines, vacuum cleaners, and air conditioners.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur