-

Hot selling high quality Chinese factory galvanized coil

The galvanized coil is made of steel as the base material and coated with a layer of zinc on the surface, which has excellent corrosion resistance and weather resistance. Its characteristics include good mechanical strength and toughness, light and easy to process, smooth and beautiful surface, suitable for various coating and processing methods. In addition, the cost of galvanized coil is relatively low, suitable for construction, home appliances, automobiles and other fields, can effectively extend the service life of the product.

-

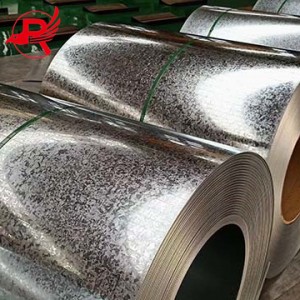

High quality hot dip galvanized steel coil Galvanized steel coil

Galvanized coil is a steel coil surface coated with a layer of zinc material. It has excellent corrosion resistance and weather resistance, and can effectively resist oxidation and environmental factors, thus extending its service life. In addition, galvanized coil shows good formability and weldability in the processing process, suitable for a variety of processing technologies, smooth and beautiful surface, widely used in construction, home appliances and other fields. These characteristics make galvanized coil widely used in many industries.

-

China factory high quality galvanized steel coil 1200mm sheet

Galvanized coil is a commonly used metal material with excellent corrosion resistance and corrosion resistance. It can effectively prevent metal materials from losing their original functions due to oxidation, thus extending the service life of parts and improving production efficiency. Strong durability, durable. Galvanized coil has a wide range of applications in industry and construction. In the field of construction, galvanized coil is often used to make roofs, walls, pipes, Bridges and other structures, with good weathering and corrosion resistance, can protect the building to maintain long-term beauty and stability.

-

Factory Cold Folled Hot Dipped DX53D Galvanized Steel Coil for Customers Demands

Galvanized coil is a metal material, by plating a layer of zinc on the surface of the steel coil to prevent steel corrosion process. Usually using hot dip galvanizing process, the steel coil is immersed in a molten zinc solution to form a uniform zinc layer on its surface. This treatment can effectively prevent the steel from being eroded by air, water and chemicals, and extend its service life. Galvanized coil has good corrosion resistance, high strength and hardness, good processing performance and decorative performance. It is widely used in construction, furniture, automobile manufacturing, power equipment and other fields. In the construction industry, galvanized rolls are often used to make components such as roofs, walls, pipes and doors and Windows to improve their corrosion resistance and aesthetics. In general, galvanized coil is an important metal material that plays an important role in protecting steel from corrosion and extending its service life.

-

Construction Material High Quality Hot Dipped Galvanized Steel Coils z275

galvanized coils, is a metal material that prevents corrosion of steel by plating a layer of zinc on the surface of the steel coil. Galvanized coils are usually hot-dip galvanizing, in which the steel coil is immersed in a molten zinc solution so that a uniform zinc layer is formed on its surface. This treatment can effectively prevent the steel from being eroded by air, water and chemicals, and extend its service life.

Galvanized coil has good corrosion resistance, high strength and hardness, good processing performance and decorative performance. It is widely used in construction, furniture, automobile manufacturing, power equipment and other fields. In the construction industry, galvanized rolls are often used to make components such as roofs, walls, pipes and doors and Windows to improve their corrosion resistance and aesthetics. In the automotive industry, galvanized coils are used to make body shells and components to increase their weather resistance and durability.

In general, galvanized coil has good corrosion resistance and mechanical properties, and is an important metal material that plays an important role in protecting steel from corrosion and extending its service life.

-

Hot Dipped S320 GD Cold Rolled Galvanized GI Carbon Steel Coil for Sales

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

DX54D Cold Rolled Galvanized / Galvanised Steel Coils for PPGI

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

DX51D Z275 Z350 Hot Dipped Galvanized Steel Coil

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

Hot Sales DX51D Z275 Zinc Coated Cold Rolled Hot Dipped Galvanized Steel Coil

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

Factory Hot Dipped Cold Rolled JIS SGCC Galvanized Steel Coil

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

Cold Rolled DX51 Hot Dipped Galvanized Steel GI Coil Prices

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

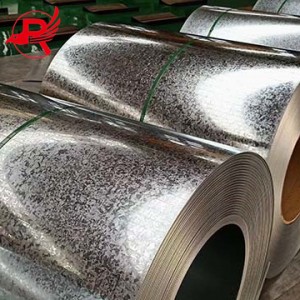

Big Spangle Galvanized Cold Rolled Q235 Carbon Steel Coil Suppliers

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur